Glatt Granulator High Shear TR16002 #5G3987. Manufacturer: Glatt. Glatt, TR16002, Stainless steel wet or dry granulations screener to a selected particle size. Features a 4.5 gallon hopper, a 6" diameter discharge at 34"H. Quick Sieve can be used for the de-lumping or milling Carol Stream, IL, USA.

2020/04/24 · Dehydration principle of dry and wet separation of pig manure. 2020/04/24. When the fresh feces are dehydrated, the solid-liquid separation equipment is needed. For example, the pig farm needs to use the pig manure dry and wet separator to separate the solid manure and urine, so as to reduce the moisture content of the material.

It is a process machine widely applied during production, for example, the production of tablets, capsules, granules, and other wet granules. It has many functions such as mixing, granulating, etc. The main machine adopts the most advanced design concept of SAR LABORTECNIC Company. The pot is of a conical structure.

2019/12/23 · Wet type granulation facility for sale Model: SXJZ-600 Installation Angle: 2 -2.5 Moisture of Feeding Materials: 20%-40% Size of Feeding Materials: 50 mesh Dimensions(mm): 4100×1600×1150

2020/02/12 · About Wet Granulator – (Oscillating) (SWG) This machine is equipped with an oscillating rotor suitable to manufacturer wet granulates of various granule sizes. Sieves are easily exchangeable. Rotor, sieve and all parts coming in to contact with the material are constructed of stainless steel. Each apparatus is supplied with one sieve.

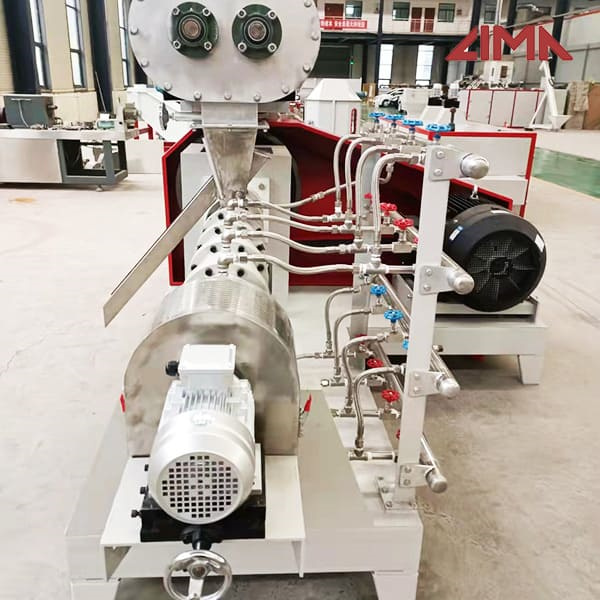

wet type granulator manufacturer/supplier, China wet type granulator manufacturer & factory list, find qualified Chinese wet type granulator manufacturers, suppliers, factories, exporters & wholesalers quickly on Made-in-China.com.

The GSC compact/sound proof granulators are designed with a complete sound proof enclosure resulting in an extremely quiet operation. Different rotor designs are available in widths ranging from 300 mm to 1400 mm with a diameter of 300 mm. The completely welded cutting chamber in conjunction with the "V" type rotor design ensures dependability

Granulator Wet Granulatorgranulator GHL Series High Shear Granulator Wet Granulator. $40,000.00/ Unit. 1 Unit (Min. Order) 2 YRS CN. Supplier. Contact Supplier. Compare. Top sponsor listing. Add to Favorites.

High quality Bio Organic Fertilizer Production Line Pig Manure Granulator Wet Granulating Type from China, China's leading fertilizer granule machine product, with strict quality control fertilizer pellet machine factories, producing high

Rotary Drum Fertilizer Granulator. Product introductionRotary drum fertilizer granulator is a molding machine that can make material into a particular shape. The rotary drum granulator is one of the key equipment of the organic and compound fertilizer industry.It is

The moisture of raw materials is about 30%. And the moisture content of output product is about 15-20%. The size of the raw material is preferably 50-200 mesh. In addition, the finished fertilizer granule size is 2mm-5 mm. The granule is more beautiful and the bigger size granule rate is less than 10%, if you use our new type organic fertilizer

2019/12/13 · Wet granulation machine works with wet granulating method. If you use liquid in the agglomeration of the raw materials, then it is a wet granulation process. People has invented and developed wet pelletizing for a very long time. And we widely use the new wet pelletizing technique. Wet granulation machine is very useful during the process.

2021/09/15 · The most commonly used formula for scaling impeller speed is power law correlation as shown in following equation. n is a constant depending on the rule: (i) for constant tip speed, the value of n = 1.0; (ii) for constant shear stress, the value of n = 0.8; (iii) for constant Froude number, the value of n = 0.5.

New Wet Type Granulator products manufacturing in China, with stylish and cool design emerge. Source new and latest Wet Type Granulator products in 2022 from credible China manufacturers, suppliers and factories. Contact most

2021/05/24 · Fluid bed dryer. At times, this process may result in material loss via attrition. In summary, wet granulation process involves 4 main stages – preparing material, wetting powder, nucleation and drying. Next, let’s have a quick overview of the advantages and disadvantages of the wet granulation process.