2020/11/06 · Low pressure extrusion technologies for converting wet powders into free flowing granules. This equipment, from Fuji Paudal of Japan, transforms wet mass powder into well-formed cylindrical, dust free, extrudates of a controlled diameter. Depending on the desired end use, the wet extrudates will either be spheronized or dried to produce various

Disc Type Granulator Machine, Capacity: 300 Kgs Per Hour 1.65 Lakh Get Quote 0.1 to 30mm Automatic Copper Wire Granulator Machine For 50Kg/hr, Wire Gauge: 20-25, Stranded

2016/03/28 · Granulation is the process of joining multiple particles or grains together, typically using a binding agent although mechanical force has been used to bond the particle together as well. This brief will provide the reader with a basic understanding of the options available for wet granulation as well as the processing implications.

India is one of the 17 Mega biodiverse countries in the world and accounts for 7-8 % of the recorded species. The State of Assam is a constituent unit of the Eastern Himalayan Biodiversity Region; one of the two biodiversity “Hot Spots” in the country. The climatic condition and wide variety in physical features witnessed in Assam have

2019/12/19 · It is suitable for you to use Tondga wet granulation equipment for your both organic and compound fertilizer manufacturing. Here you can know the detailed wet granulation process for making fertilizer granular. Put powdery materials into plate type wet granulation equipment. For your information, the moisture content of your material had better

2022/03/04 · The alluvial soils of Assam can be further be divided into two sub-types base on some micro differences in character such as – younger alluvium and old alluvium. The younger alluvial soil occurs in an extensive belt of the north-bank and south-bank plains including the active flood plains of the Brahmaputra and the Barak rivers.

2021/06/23 · 1200. 2900 X 2900 X 2500 (3200) Salient Features of Rapid Mixer Granulator. RMG Process Unit. Air purged shaft seals eliminating powder entering the seal. Built in cleaning system for both shaft seals. Layouts to suit indicidual requirements possible. Machine can be provided with loading & unloading units to form an assembly line & reduce

2019/07/29 · Wet Granulation Process Overview. In wet granulation, powders are bound together using adhesives rather than by compacting as in the dry granulation process. The adhesive (usually called a binder) is incorporated in the form of a solution or suspension in a suitable liquid. The liquid should be non-toxic and is preferably water, although

2021/05/24 · Fluid bed dryer. At times, this process may result in material loss via attrition. In summary, wet granulation process involves 4 main stages – preparing material, wetting powder, nucleation and drying. Next, let’s have a quick overview of the advantages and disadvantages of the wet granulation process.

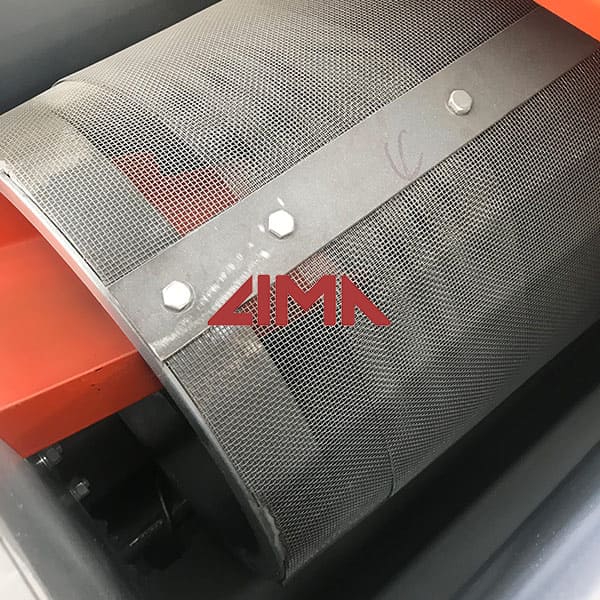

2020/02/12 · About Wet Granulator – (Oscillating) (SWG) This machine is equipped with an oscillating rotor suitable to manufacturer wet granulates of various granule sizes. Sieves are easily exchangeable. Rotor, sieve and all parts coming in to contact with the material are constructed of stainless steel. Each apparatus is supplied with one sieve.

2021/09/15 · The most commonly used formula for scaling impeller speed is power law correlation as shown in following equation. n is a constant depending on the rule: (i) for constant tip speed, the value of n = 1.0; (ii) for constant shear stress, the value of n = 0.8; (iii) for constant Froude number, the value of n = 0.5.

Find 2022 quality & cheap wet type granulator for sale. You can get inexpensive wet type granulator with discounted price from the most reputable wholesalers. Explore App

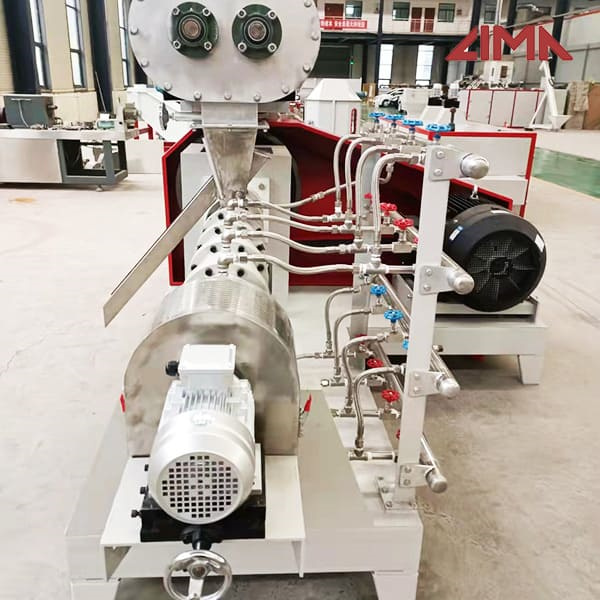

The Series wet type granulator Integrity comes to the firstSeries wet type granulator. Series wet type granulator . Applications: This machine is widely used in pharmaceutical, fo + 86 19337889085 sale@limamachinery

2020/07/09 · Advantages: Process a broad range of starting materials, including all kinds of manure, horse manure, chicken manure, pig manure, etc. Potential for high density granules. The high pellet rate can be reached up to 93%. Therefore, it can help you reduce materials to waste for making fertilizer pellets. Meanwhile.