Frequency. 50 Hz. Semi-Automatic Feed plant is used for manufacturing feed where the land is available freely. Because these types of plant require more ground space as compare to the Automatic Plants. Semi-Automatic Feed Plants are the plants where we don't use too much structure. Automatic Plants are simple in design.

2021/06/22 · B esides, except floating fish feed extruder machine, we have sinking type feed pellet mill for making sinking pellets. Wet Type Fish Feed Extruder Machine Wet type fish feed extruder machine is widely used for producing grains into high-grade aquatic feed pellets for many kinds of pet like fish, catfish, shrimps, crab, cat, dog and etc. Grain materials employed

DSP Series Wet Type Fish Feed Extruder for Sinking Fish Feed Pellet Production.You can change different molds to make pellets with different diameters. Fish feed pellets can float on the water surface without dissolution for over 12 hours. The fish

2021-1-11 · dry type fish feed pellet machine and wet type fish feed extrusion machine,As the major part of fish feed production plant, wet type fish feed extruder is equipped with a boiler which can continuously providing hot

2018/11/21 · All other available sturgeons species should be kept in a minimum of 3,000 gallons (again, per sturgeon), and if you’d like to have a beluga don’t even think about it unless your pond is at least 15,000 gallons. Your pond should be a minimum of 4 feet deep for any sturgeon, though 10 to 15 feet is best as they prefer deep waters.

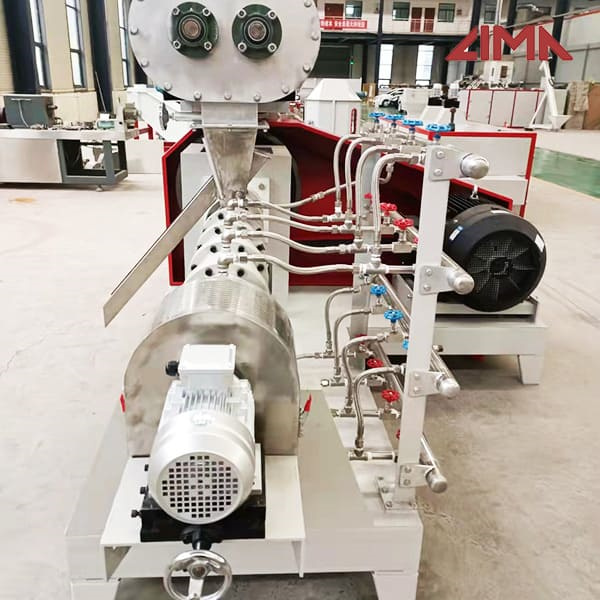

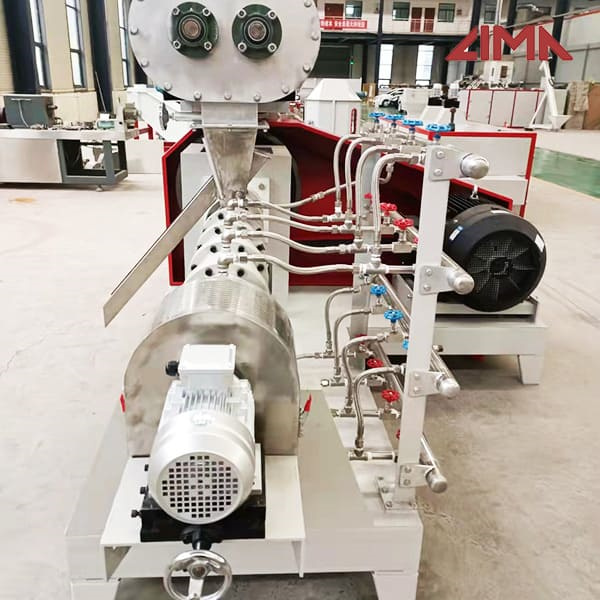

Wet Type Feed Extruder. Feed extruder machine is the essential equipment in fish / pet food production line. There are two types of fish / pet food processing extruder: wet-type and dry-type. Wet type extruder is designed with a boiler which can produce steam throughout. widely used to produce all types of feed for aquatic fish (catfish, crabs

Wet Type Floating Fish Feed Plant Introduction Our wet type floating fish feed pellet production line is the complete procedure of fish feed producing plant, which include fish feed making machin e, fish feed crusher, fish feed mixer, fish feed dryer, and other equipment.

![<h3>List of Sturgeon Species 2022 [Updated] - Pond Informer</h3>](/wp-content/themes/lima/load/50/floating fish feed pellet making machine68.jpg)

2021/05/22 · Modern-day sturgeon species are grouped under 4 genera: Acipenser, Huso, Scaphirhynchus, and Pseudoscaphirhynchus. Most sturgeons are found in temperate and sub-arctic environments in Europe, Asia, and North America. As bottom-feeders, they typically spend most of their lives in nutrient-rich rivers and estuaries.

2018/11/28 · Advantages of Wet Type AquaFeed Extrusion Plant. 1. Advanced wet extrusion technology, high capacity and low energy consumption. 2. The feed pellet line occupies less floor space and needs low investment in construction work. The modular structure is convenient for assembly and disassembly, facilitating the shipment and installation. 3.

Name: Wet Type 1 T/H Fish Food Processing Machine Paking To Ukraine Capacity: 1-1.2t/h Crusher Machine Capacity: 3t/h Mixer Machine: 5.5t/h Application: Kinds Of Aqua Fish Food Shipping: By Sea High Light: 1T/H Floating

However, the decline of Danube sturgeons is clearly documented by the rapidly decreasing catches. Already at the beginning of the 16th century, catches of Beluga Sturgeon dropped in the Middle Danube, and in the 18th century fishing of migratory sturgeons in the Upper Danube was abandoned due to their scarcity. The Lower Danube continued to be

2019/07/22 · Basic feed mill equipment operations for making animal or poultry feed pellets include Raw Material Receiving, Grinding, Batching, Mixing, Pelleting, Cooling, Sifting, Packaging and Warehousing. Raw material receiving. Feed mills are usually equipped to receive both rail and truck delivery of grains and other ingredients.

Amazing making chicken feed layers At Fabulous OffersGrab unrivaled making chicken feed layers on Alibaba.com and bolster your productivity. The making chicken feed layers are sup Tel :

2020/07/22 · Working Principle of Wet Type Fish Feed Extruder Machine Fish feed extruder can also be named as technological process, it forces raw materials into one or more of following process such as mixing, heating, pasting, cutting, extruding, etc. flow through the die, making material eruption gasification.

Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditioning of the raw material. Different molds are available to make pellets of different diameters (0.9-15mm) and shapes.