150*61*180. This pellet press equipment is also called wood pellet mill or feed pellet mill, as it is mainly used to make pellets from grains and various woods. Moreover, it can also make pellets from other biomass materials, like: grass, bagasse, peanut shell, cotton and corn stalks, and other agricultural residuals.

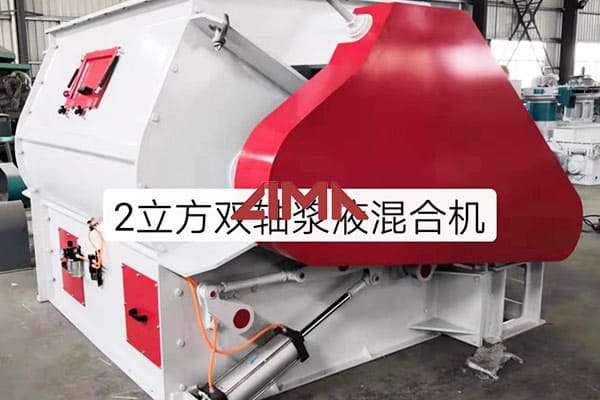

Feed crushing machine Feed Mixing Machine Fish Feed Machine Fish Feed Production Line Poultry Feed Machine Flat Die Poultry Feed Pellet Making Machine Ring Die Poultry Feed Pellet Making Machine Poultry Feed Machine Line Chicken Feed Pellet Line 1-2t Chicken Pellet Line 100-1000kg

May 23, 2020 · Operate the pellet mill. step 1: Grinding before use. Because most of the pellet mill die presses in pellet machines are heat-treated parts. After planing, drilling, milling, quenching, etc., there are many burrs in the inner hole or surface, which affect the efficiency of granulation.

The Poultry Feed Pellets Making Machine* is one of the offered models for the Pellets Making Machine. Feeding the poultry with pellets is very advantageous as it helps in easy digestion of food. For preparing the poultry feed pellets, the raw material(s) need to be converted into powdered form. Rajkumar Feed Grinder can be used for the same.

Small poultry feed mill machines used for 800~1000kg/h mini animal feed pellet line. Suitable for making boith complete feed and concentrated feed of poultry, cattle, livestock and animals. This feed mill plant unit are widely applied to small to medium scale production of animal feed pellets. It can produce 800~1100kg pellet feed per hour.

professional animal feed pellet mill with low priceAnimal feed pellet mill machine becomes more and more popular and widely used in small medium husk,straw meal,grass meal ,alfal + 8617337771729

Working Principle Of Poultry Feed Pellet Machine. The working principle of the ring die poultry feed pelleting machine: The mixed powder with a moisture content of not more than 15% enters the feeding screw conveyor from the bin to be granulated, and the appropriate material flow is obtained by adjusting the speed of the feeding screw conveyor shaft, and then enters the conditioning device for

Hot sale!Farm equipment 1-30t/h chicken feed machine poultry feed pellet press mill Liyang Rongda Machinery Co., Ltd.

High-capacity, modernized and biomass poultry pellet press machine at Alibaba.com for both residential and commercial uses. These poultry pellet press machine are perfect for making sawdust pellets.

1 ton/h feed milling machine. $10,000~$20,000. 3 ton/h animal feed process company (both making mash feed and pelleted feed) $60,000. 5 ton/h cattle feed process line. $70,000~$80,000. 10 ton/h feed manufacturing plant. over $100,000. Note: When it comes to project investment cost, you need to consider raw materials, workshop rent, equipment

The Poultry Feed Pellets Making Machine* is one of the offered models for the Pellets Making Machine. Feeding the poultry with pellets is very advantageous as it helps in easy digestion of food. For preparing the poultry feed pellets, the raw material(s) need to be converted into powdered form. Rajkumar Feed Grinder can be used for the same.

This is a 15TPH poultry feed plant project we built for client in domestic. It consits of whole pellet production section from crushing to packing. The raw materials can use corn/maize flour, barley flour, wheat bran, rice bran, cassava flour etc which will provide energy feed for poultry. Outside View of Poultry Feed Plant Project. Crushing ...

A chicken pellet making machine can be used to make pellets for cattle feed, pig feed, chicken feed, horse feed, duck feed, fish feed and even rabbit feed. The machine comes in different sizes depending on the intended feed production capacity it can be as low as 50 kg/hour to above 1 tonne/hour. And, different die diameters allows to make the

Working Principle Of Poultry Feed Pellet Machine. The working principle of the ring die poultry feed pelleting machine: The mixed powder with a moisture content of not more than 15% enters the feeding screw conveyor from the bin to be granulated, and the appropriate material flow is obtained by adjusting the speed of the feeding screw conveyor shaft, and then enters the conditioning device for

Contact: 01676335877, 01911906334. E-mail: info@crescentintbd.com, syedmonjurrahman2@gmail.com . Website: www.crescentintbd.com