Grab unrivaled poultry feed pellets crumbler on Alibaba.com and bolster your productivity. The poultry feed pellets crumbler are super-efficient and come with unequaled deals.

poultry feed pellet crumbler machine manufacturer/supplier, China poultry feed pellet crumbler machine manufacturer & factory list, find qualified Chinese poultry feed pellet crumbler machine manufacturers, suppliers, factories, exporters & wholesalers quickly on Made-in-China.com.

CPM pellet crumblers are high-capacity, high-efficiency machines with a heavy-duty design and user-friendly features. Count on years of continuous, reliable operation. CPM pellet crumblers range from 10 to 40 tons per hour and can be constructed to match the output requirements of your process. Extensive field research has proved that CPM

poultry feed pellet line (500-1500kg/h) of conveyors e.c.t . For Poultry feed pellet line details , as below : 1. poultry feed pellet line makes 2-8 mm diameter feed pellets . such as 2-4mm diameter chick feed pellets and pig feed pellets .1.5-3mm fish feed pellets ,2-5mm rabbit feed pellets ,4...

The pellet crumbler is essential equipment in feed pellet production, which is dedicated to crumble large feed pellets into irregular small ones to meed different demands of different animal in different growth periods. It is suitable for crushing the feed pellets of various sizes to 0.6-1.5mm (fine tooth type) or 1-2.5mm (common tooth type).

This is a special designed crumbler that Ø3-5mm pellet feeds crumble into small pieces. The design helps benefiting from the quality of the granule and pellet feeds. It is used mostly for poultry animals, fattening pellets, aqua pellets. High efficiency with rollers. There are two rollers that allows adjusting (manually or with the motor) the gap distance in the pellet crumbler.

A crumbler is used to obtain precise size feed specifically for poultry and prawn feeds. Fitted below the pellet cooler with adjustable rollers, a crumbler can produce required size of crumbs. The Cremach crumble technology is based on two large, independently driven rollers. That ensures an optimum result of minimum fines with maximum crumble.

1. Roller crumbler is special purpose equipment to crumble big pellets into small pellets. 2. Roller crumbler can crumbled pellet into 0.6~ 1.5mm or 1~2.5mm; 3. Roller crumbler is widely used for crushing poultry and livestock pellets . 4. The finished product has smooth appearance and low powder content. 5.

In animals’ (poultry and livestock) different growing periods, they need different size feed particles. Therefore, the feed pellets crumbler is used to break large size feed pellets into smaller particles. Sometimes, if the feed pellet mill directly presses feed into required small size feed, its output is low and the energy consumption is large.

Colorado Mill Equipment currently offers five pellet mill models with additional models to be added soon. The flat-die millennium series mills are the simplest pellet mills ever built. Designed with ease of operation and low maintenance cost in mind, they provide an ideal solution for a small-scale operation, or lab and R&D application.

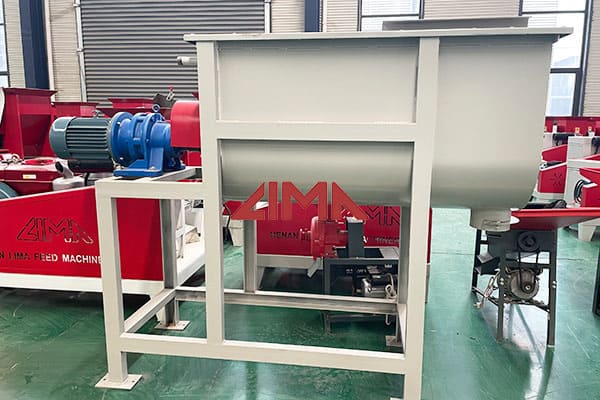

Whatsapp: +86 18574103366. Wide Application. High Efficiency. Easy Maintenance. Strong Durability. SSLG Series Pellet Crumbler. Richi Crumbler is a kind of feed processing equipment that crushes the larger pellet feed products produced by the pelletizer and cooled by the cooler into the smaller pellet feed products.

Usually, it is used in feed pellet production line and after cooling pellets, instead of adopting small-hole ring die. The pellet crusher which will increase the production capacity and save energy. Feed Pellet Breaker Structure Feed pellet breaker is equipped with a gap adjustment device between rolls to get the required particle size of feed.

Small Size Double Roller Poultry Feed Mill Machiney For Big Pellets Chaff Cutting Our company is manufacturing triple roller crumbler,double rooller crumbler,and many different kinds of pellet mill and hammer mill. Product Description Features 1. It is..

Here are some approximate project costs for your reference: 1 ton per hour mash feed production line: The equipments cost about 1,6000USD. 2~3 ton per hour animal feed processing plant for making both mash feed and feed pellets: About 6,5000USD. 5 ton per hour poultry feed mill plant for making both mash and pelleted feed: About 140,000USD.

Feed Crumbler Machine. ₹ 1.25 Lakh Get Latest Price. Crumbler is a machine used to crumble a whole pellet into smaller portions by passing through a pair of rolls, spaced at a certain distance and moving in opposite directions. - Very good throughput in terms of size. - Standardised material for rolls to give more life.