The high cost of imported livestock feed and the importation of relatively cheap pig and poultry meat, mainly coming from Australia, New Zealand and Canada has resulted in a reduction in the number of pig and poultry producers in Tonga over recent years. This project aimed to establish a local livestock feed manufacturing

The parts th at make up the livestock feed. pelleting machine are the frame, barrel, hopper, screw conveyor or auger, die, pulley and motor. The machined components were made of mild. steel

Manufacturer of Animal Feed Mill Machine - Flat Die Pellet Machine, Floating Fish Feed Making Machine, Mild Steel Screw Conveyor and Counter Flow Cooler offered by Sivaselvi Engineering, Udumalpet, Tamil Nadu.

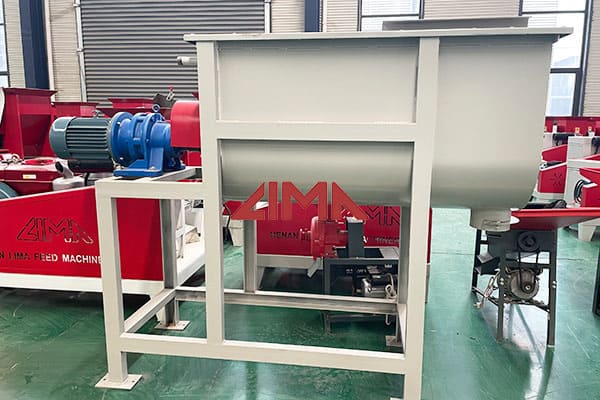

1. High homogeneity: This kind of diesel feed mixer machine design reinforces convection, shearing, and mixing effects.To distribute materials with different characteristics as evenly as possible. 2. Human friendly: Simple and reasonable structure, convenient maintenance, reliable, safe, effective and less investment.

The 3-5TPH fully automatic poultry feed plant is a complete set of livestock and poultry feed pellet production project solutions. The project chooses to use the process of batching first and then crushing. It is mainly divided into six parts: raw material receiving, cleaning and batching section; crushing section; mixing section; granulating

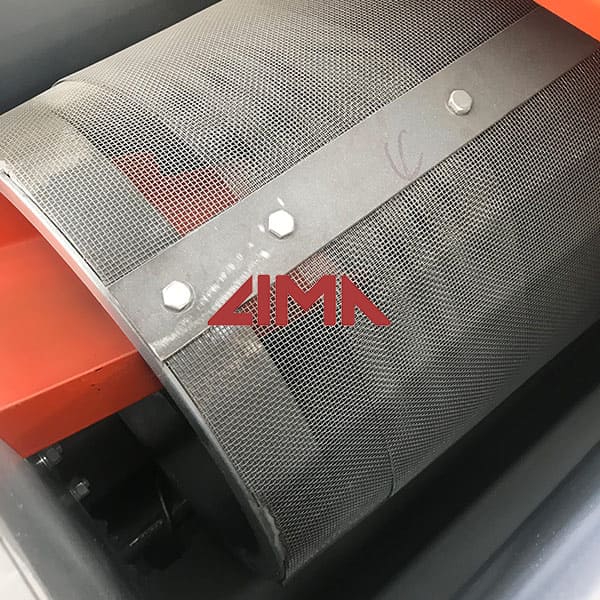

This study was conducted to design and evaluate the performance of an electric motor-driven pellet mill for animal feed production. The designed pellet mill is composed of major parts like feed hopper, pelleting chamber, pellet roll, die plate, discharge chute, and frame. It is driven by a 1.5 Hp electric motor.

Mash Pellets & Crumbles Textured Feeds Miscellaneous . Product Mix Bagged Feeds Feed Mill Design Author: Default Created Date: 3/5/2012 6:38:14 PM ...

Pigeon Pig 70KW 3T/H Livestock Animal Feed Making Machine all kinds of animal feed powder usually for poultry feed , cattle,cow, sheep . etc. Strongwin complete sets of livestock and poultry feed processing equipment can be refined to design complete sets of chicken feed processing equipment suitable for broilers,...

Apr 03, 2006 · Andrews (1991b) has described feed quality-control programs as: “A system for making sure that proper standards are maintained through use of periodic inspections.”. Any good feed quality-control program contains four components: Ingredient quality; Process control; Finished feed quality, and.

Let us work together to create a better future! Blog animal feed factory machine cost nigeria

The design computations to handle a 50Kg mass of feed was done in the MS Excel environment for proper machine design approach. The machine was designed using proper material selection was done before the assembling and fabrication of parts. The efficiency of the machine, its associated cost of production and the product obtained after few

With this rate, the pelleting machine can produce daily nearly half a ton of feeds for an 8-hour operation making it more ideal for community feed milling or for even just a small-scale feed miller. Considering that the CPU- CARES Formulated Starter Mash will be used to pelletize, financial analysis indicated that it will be profitable to

The ABC Hansen concept of Mini Feed mills has grown rapidly in popularity for the 50 grams of feed daily or some 1,200 cattle at 9 kg of feed, excluding roughage per day. The key to good end products are high buoyancy of extruded pellets, pellet mills and dies, and with more than 2,000 pellet mills in the market.

Mar 30, 2018 · Feed production requires careful management and the process of production. Feed generation for animals, poultry or oceanic life includes a scope of exercise, which incorporates granulating, blending, pelleting and drying operations. 1 There is high feasibility of the utilization of various forms of farm and agro-industrial wastes and by-products in the formulation of complete feeds for

The chicken feed making machine is an ideal equipment for chicken broiler layer breeding. It is of great significance for feed maturation, increase nutrition, improve absorption, convenient storage and transportation, adapt to the chewing function of animals, and high-yield and high-efficiency livestock breeding.