Pellet machine should be installed in indoor or convertible, environment temperature is5-40oC. Process should match with the pellet mill machine's complete set of equipment. Voltage stability, deviation is not more than±5%. Before feeding, the powder material moisture should be less than 15%.

1000-1200KG/H feed pellet mill. Straw pellet mill is a kind of pellet press used to make pellets from biomass materials for heating purposes. The raw material can be wheat straw, rice straw, and other similar agro waste.Straw is a generic term used to refer to residues that remain from harvesting grain plants such as rice, corn and wheat among

For detail and price of grass pellet mill, please refer to: Email: palet@biopelletmachines.com. Mobile: +86-13406817961. Note: Please feel free to give your inquiry in the form below. We will reply to you with details within 24 hours! Your Name (required) Your Email (required) Your Message.

Satake design and build feed milling plants for poultry, livestock and aquaculture feed production. Plants can be designed to produce pelleted or mash feed and include all the equipment necessary for a ‘turnkey’ solution. Many of Australia and New Zealand’s largest feed mills have been built by Satake.

The animal feed pellet mill is mainly driven by the rotation of the die plate to drive the rotation of the built-in pressing roller to quickly squeeze corn, soybean meal, grass fodder, green fodder, etc. into pellets. Feed pellets processed by the commercial animal feed pellet machine can usually be used to feed cattle, sheep, chickens, pigs

Grinding & Pellet Making Equipment. We offer two pellet mill sizes: HB100 7.5 kw (10 HP) HB 200 15 kw (20 HP) Make your own pellets from just about any material — alfalfa, hops, grass, wood, hemp, municipal waste (MSW), algae, biomass etc for use as feed, fuel, fertilizer, litter or anything you require.

Grass is the main food of herbivores, like cattle, horse, rabbit, sheep etc. So, the grass pellets can be used to feed livestock. Compared to grass, grass pellets are convenient for storage and transportation. They contains less dust and debris, are more easy to digest for the animals than common grass.

Fertilizer & Digestate Pellet Mills - ELF Pellet Making Poultry litter pellets made in a 3-mm size crumble are ideal for spreading on fields or bagging as a retail product.

May 04, 2017 · In addition, the grass pellet fed to the livestock in winter, enable the livestock get more nutrients, so we can gain more meat, and milk. Storage conveniently. The grass after compressed by the pellet machine turn into grass pellet, its volume is decrease greatly. So that it is convenient to storage and transportation.

Making Grass Pellets for Feed. When processing compound feed pellets from forage grass for various livestock and poultry animals, the grass is mixing with 55%~60% toppings (green hay, straw stalk, etc), 35%~40% concentrate (corn, sorghum, oats, wheat bran, etc), 3%~1% minerals and vitamins. Then the mixed fodder can be pelletized.

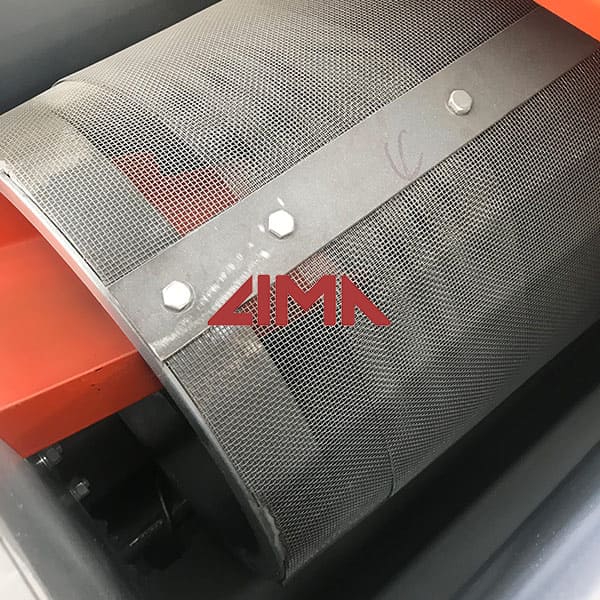

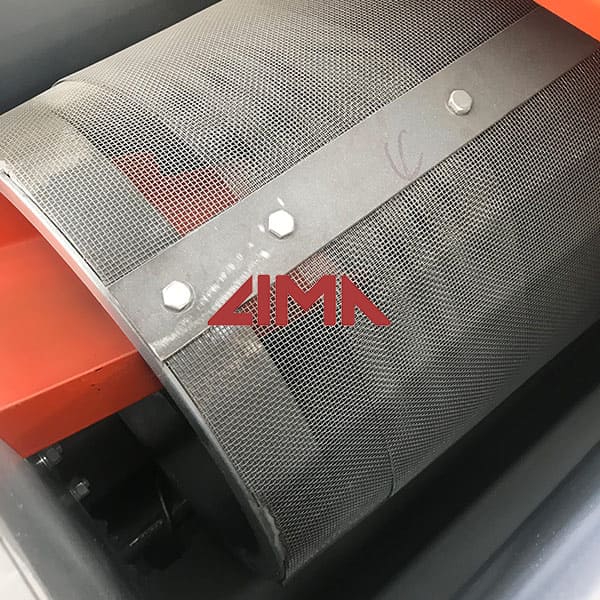

Turn on the grass pellet machine and put the crushed grass meal into the pellet mill, then it will begin to work. The raw material will enter the pelleting room. The flat die will press the grass and squeeze the raw material into the hole. And then the raw materials are formed into the cylindrical pellet. The cutting knife will cut the pellet

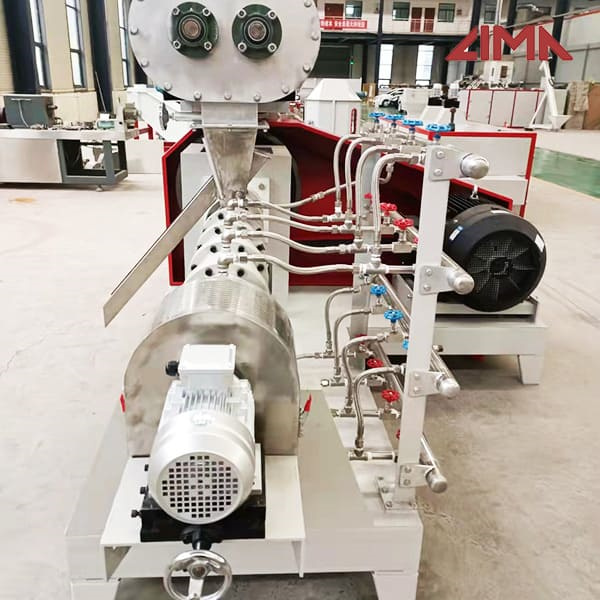

The feed pellet machine is a kind of equipment mainly used to make animal feed, generally using biomass such as soybeans, forage, straw, rice husk, and corn as raw materials. After the material is crushed and stirred, the pellet machine will extrude them into particles with uniform size and neat shape. The smooth-grained feed processed by this

Feed Mill Systems | Design, Layout, & Engineering of Grain, Feed, & Feed Mill Design Services Dwight Kinzer, dba Process Equipment & Design LLC specializes in the Process Flow Dia + 8617337771729

Oct 11, 2018 · Ingredient and Effect of Pellet Feed. In order to produce various feed for livestock and poultry as well as improve the utilization rate of feed, to mix toppings (green hay, straw stalk) 55% 60%, concentrate (corn, sorghum, oats, wheat bran, etc.) from 35% to 40%, minerals and vitamins 3% and 1% of compound feed as the components, and compress them into pelleted feeds with granular feed

Sep 01, 2019 · pellet mill off if there is no flow to the bearings. There is also a pressure-relief device in the system that is normally set to operate at approximately 4 Bar. Figure 3-2. Circuit lube system in a gear-driven pellet mill. Lubrication Gear-driven pellet mills are now fitted with integrated circuit lube systems (see Figure 3-2),