Good Quality 8-12 T/H Feed Pellet Production Line. Good Feedbacke 5-7 T/H Feed Pellet Production Line. Easy to Use 3-4 T/H Feed Pellet Production Line. Easy to Operate 1-2 T/H Feed Pellet Production Line. Shrimp Feed Pellet Making Plant. Fish Feed Pellet Mill Plant. Cattle Feed Pellet Making Line. Chicken Feed Machine Production Line

The reduction of moisture content. ≥3.5%. Mixing timePressure of air. 0.002MPa. Absorbing Air Quantity. m3/min·t. Send Email Chat now. Share With :

Aug 25, 2018 · The counterflow pellet cooler is applied for efficient cooling of hot and moist pelleted products with good flowing capabilities. Typical applications are for cooling of feed pellets and wood pellets. It can reduce the temperature of pellets from 80~90℃to about 3~5℃ above ambient temperature. And the pellet moisture content is reduced from 17%~18% to 12%~13%.

The brand new good efficiency livestock feed ruminant feed pellet swing cooler principle is adopted to cool the pellets with high temperature and moisture. Hot air touches hot pellets and cool air touches cool pellets so as to avoid the pellet surface crack caused by sudden cooling produced by direct touching between cool air and hot pellets.

Liyang Manufacturer Supply Biomass Pellet Refrigeration Equipment Vertical Cooler , Find Complete Details about Liyang Manufacturer Supply Biomass Pellet Refrigeration Equipment Vertical Cooler,Biomass Pellet Refrigeration Equipment Vertical Cooler,Vertical Cooler Factory,Vertical Cooler Price from Supplier or Manufacturer-Liyang Weifeng Equipment Co., Ltd.

Counter Flow cooling technology can be used for a variety of products including, Livestock feed pellets, pet food kibble, soy cake, and other pressed/form products. Key Features: Round design allows the most efficient use of air flow that minimizes CFM requirements compared to other designs

1.The pellet cooler takes advantage of counter current cooling principle to cool the pellet material with high temperature high humidity. It can avoid the shock cooling phenomenon when the cold air contacts with the hot material, thus can prevent the pellet appearance generating crazings. 2.Cooling tank adopts octagon design, which can ensure

Mar 07, 2019 · Therefore the pellets need to be cooled to remove moisture and heat generated in the conditioning and pelleting. The preferred choice for cooling is counterflow feed pellet cooler which has been the first choice in feed pelletizing plant. 1. Cooling tank adopts octagon design, no dead angles. 2. Large inlet air area, outstanding cooling effect. 3.

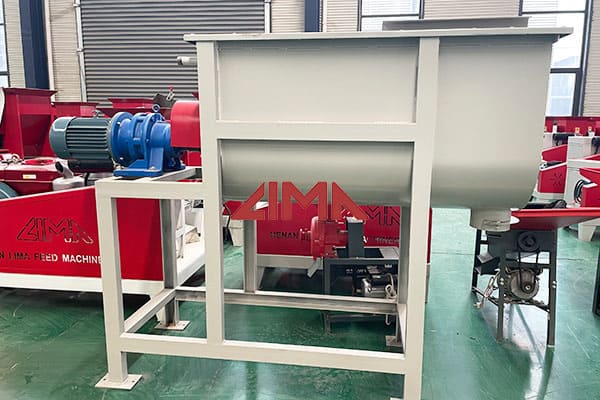

This feed pellet plant can produce 2~8mm of feed pellets with 600-1000kg/h pellet output capacity. The pellets are suitable for feeding pig, cattle, sheep, rabbit, chicken, duck, geese, fish and other animals. The grinding machine can crush the maize and soya bean meal into fine powder, then the fine powder can mix with the wheat bran, bone

Nov 21, 2018 · Both movements are opposite to each other. Hence, this design of cooler is called counter flow cooler. In addition to heat, moisture is also removed from pellet during the cooling process. The feed temperature at inlet of cooler will be around 85 C in poultry feed and around 65 C in cattle feed with molasses in ration.

Nigeria Animal Feed Pellet Press Machine. This STLP300/400 pellet machine of animal feed pellet production line can be used for processing livestock, poultry and aquatic feed pellets, which is specially suitable for medium feed factory, breed farm or aquatic base. It has the better raw material versatility, which can be suitable for pelletizing

Galen et al. (2000) pointed out is a limitation to the use of the livestock feed that pelleting feeds produced many traits desired pelleting machine because of the high cost of by livestock producers which include decreased the equipment for pellet processing (FAO, 1997; feed wastage, reduced selective feeding, Kabuage et al., 2000; Eugene, 2002).

animal Livestock feed pellet cooler cooling equipment machine to make animal food, US $ 2350 - 7000 / Set, New, Henan, China, HEXIE.Source from Xinxiang Hexie Feed Machinery Manufacturing Co., Ltd. on Alibaba.com.

Beef Cow Rations and Winter Feeding Guidelines | Cattle Fax: 306-694-3938: Mailing Address: 45 Thatcher Drive East, Moose Jaw, SK, S6J 1L8 How Much Does A Cow Cost In 2022?

Nov 21, 2018 · Both movements are opposite to each other. Hence, this design of cooler is called counter flow cooler. In addition to heat, moisture is also removed from pellet during the cooling process. The feed temperature at inlet of cooler will be around 85 C in poultry feed and around 65 C in cattle feed with molasses in ration.