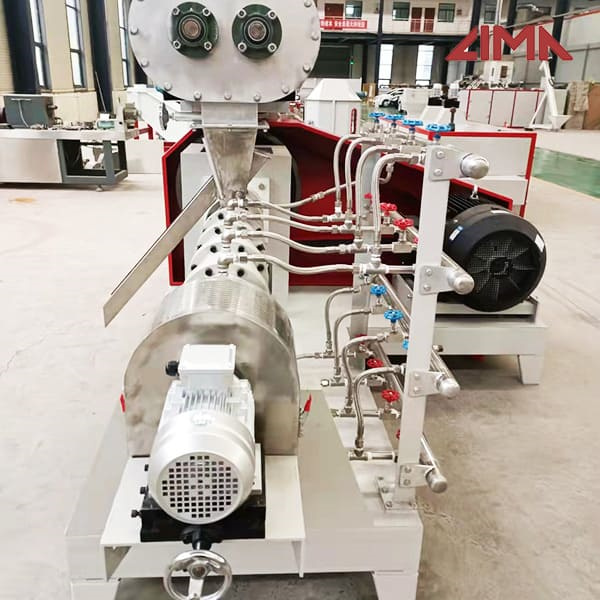

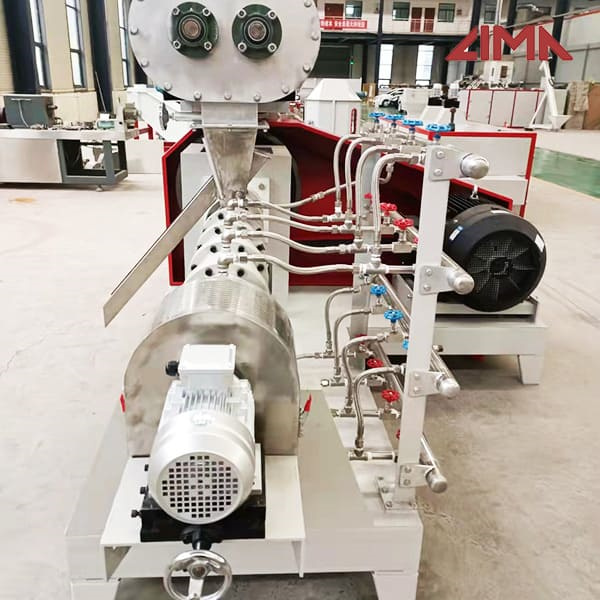

Feed Hammer Mill Features. 1. Mainly used for grinding of raw materials in small and medium-sized animal and aquatic feed processing factories. 2. Adopt imported high quality SKF bearings, stable and durable performance, low working temperature. 3. Coarse grinding and fine grinding are both available, high accuracy. 4.

Get the best deals on Hammer Mill In Livestock Animal Feed when you shop the largest online selection at eBay.com SALE! HAMMER MILL BEATERS - Hole 1-1/16" - Thick ...

Recently serviced New blades Shedded excellent condition Comes with scales and side discharge. Machinery & Equipment, Fodder and Feed Mixers, Penta. Keith, Upper South East, SA. $45,000.00 $49,500.00Inc. GST. 10/05/2022. 121 views. For Sale Listing No. 93483. View details.

en hammer mills for sale australia. The Roller Mill is a grain-crushing machine used to enable farmers to feed freshly crushed grain/s to the livestock this in turn increases the protein value to the animal. It is an effective and efficient way of processing cereal grains and legumes becoming an increasing trend in rural Australia.

2021 FARMTECH TYYKM-6 HORIZONTAL FEED MIXER + DUAL ELEVATORS (6.0M3) $43,670. Livestock Feeding / Mixer Wagons. RefCode: TA851503. System Type: Twin. Configuration: Horizontal. Number of Augers: 2. Tub Capacity - m3: 6. (6.0m3) Quality European made horizontal feed mixer. New stock is always in order to meet market demand.

Hammer mill supplier of kefid is good and manufacture hammer mill grinder machine, with the advantage technical, our hammer Hammer Mill for Sale and Professional Hammer Mill Design Feed Mill E-mail: info@feedmillequipments.com Tel: (86) 372 5965149 Fax: (86) 372 5951936 Add:Suite C, 4/F, Jinhao Business Bld., Renmin Rd. Anyang, Henan, P.R.C.

Satake ‘G’ Series Hammer Mills Satake Australia manufacture high quality, energy efficient hammer mills for the coarse grinding of poultry and livestock feeds and the fine grinding of meals for aqua feed. Our hammer mills are used in a variety of industries for grinding organics and minerals.

Hammer Mill - FA Maker +61(3) 9314 2511; [email protected]; F.A. Maker Pty Ltd 11-19 Boundary Rd, Laverton North VIC 3026 Australia Worldwide shipping get price

Livestock Feed Hammer Mill Grinder Gaining client pleasure is our company's aim without end. We are going to make excellent efforts to create new and top-quality goods, meet your special requirements and provide you with pre-sale, on-sale and after-sale companies for Livestock Feed Hammer Mill Grinder, Industrial Drying Machine , Wood Energy

Working Principle of Feed Hammer Mill. The major working part of hammer mill is rotor with hammer, which is at high speed when the raw material are putted into crushing chamber from the top of the feeding inlet, then raw materials are ground under the force of adjustable rotating hammers and friction between screen plates and gradually become small size particles.

Williams Patent Crusher & Pulverizer Co Meteor High Speed Hammer Mill. $32,500.00. or Best Offer. Hammer Mill Feed Grinder - 5hp 220v 1ph Electric Powered! USA In-stock w/Support. $2,595.00. Free shipping.

Brand New Unused- HAMMER MILL 400 x 600 Includes 17.65kw 24hp electric start diesel engine. Size:- 2400mm x 125mm x 128cm Weight:- 1280 kg/s OR 1.28tons These hammer mills are built with longevity in mind. They have replaceable liners/wear parts. Bearings have easy accessible grease points.

The SvenMill roller mills crack the grain instead of pulverizing it like a hammer mill. This allows for less fines and flour and more nutrition going to the animals. All SvenMills comes with features built for feeding livestock in the most extreme environments.

Features of our feed hammer mill. Adopt the international advanced technology, the new multi - cavity type wide chamber design. The life of hammer and sieve plate is greatly improved, especially the life of small aperture sieve plate. The rotor is designed with an innovative design makes it running more smoothly.

Features of Livestock Feed Hammer Mill. 1. Adopt advanced serpentine spring coupling and direct transmission. 2. Stable performance, strong and durable, beautiful appearance and simple operation. 3. Low consumption, high output and high efficiency. 4. The final products are in uniform fineness due to the reasonable arrangement of hammers and