The Animal Feed Manufacturers Association of South Africa (AFMA), is the official industry representative body of the South African feed industry in the livestock feed sector and larger agricultural environment. As the official representative body for the sector, AFMA positions and aligns itself by identifying the business environment that will

![<h3>Livestock Feed Mill Business Plan [Sample Template for 2022]</h3>](/wp-content/themes/lima/load/50/floating fish feed pellet making machine63.jpg)

Constructing of feed mills to produce livestock feed – $10,000. Other start-up expenses (POS Machines, utilities, signage, business cards and stationeries) – $3,000. Purchase of truck for use in operation – $50,000. Purchase of furniture and devices (computers, printers, photocopiers) for administrative section – $3,000.

In this South Africa straw pellet plant project, straw pellets are used for feeding cattle and sheep. On February 15, 2021, South African customers consulted with us: "Want to make animal feed pellets with wheat straw as roughage." On May 19, 2021, this South Africa livestock feed mill for making straw pellets for animal feed project was signed.

2022. 4. 8. · Animal Feed Produciton Line Solutions Focusing on the feed pellet processing industry for more than 20 years, RICHI Machinery has provided professional project guidance, equipment production, production line construction, management and operation and other product services to thousands of customers, and together they have proved the strength of China's

We can customize feed production plant, turnkey project ♦ 1-30 t/h chicken feed manufacturing plant / feed mill plant; ♦ small scale feed mill plant for animal; ♦ 1-30 t/h cattle feed plant project; ♦100-4000kg/h Floating fish feed mill plant; ♦ 1-30 t/h poultry feed mill project; ♦ 1-30 t/h livestock feed plant project;

Maize Milling Machines for Sale in South Africa – Buy High Quality Maize Milling Machine The small maize milling plant provided by ABC Machinery is the HOT sale maize processing m Tel : + 8618236939453

Pig Feed Making Machine Sanjivani Agro. Makka Chunni Plant, For Cattle Feed Making, 1 Ton/Hr. Animal Feed Making Machine Sanjivani Agro Machinery. 250kg/Hour Poultry Feed Crusher, 300 kg per hr. Painted Full Automatic Makka Bharda Plant, Three Phase, 500kg/ Hr. Cattle Feed Plant, 200-250 kg per hr. Poultry Feed Grinder Machine, 1500 kg per hr.

5. Marketing. 1. Feed Formulation. First, you have to come up with a formula. This would depend on the livestock category you want to produce for. Of course, the formula for chicken feed would be different from fish feed. To come up with a good formula, you should learn about the nutritional requirements of the category of animals you want to

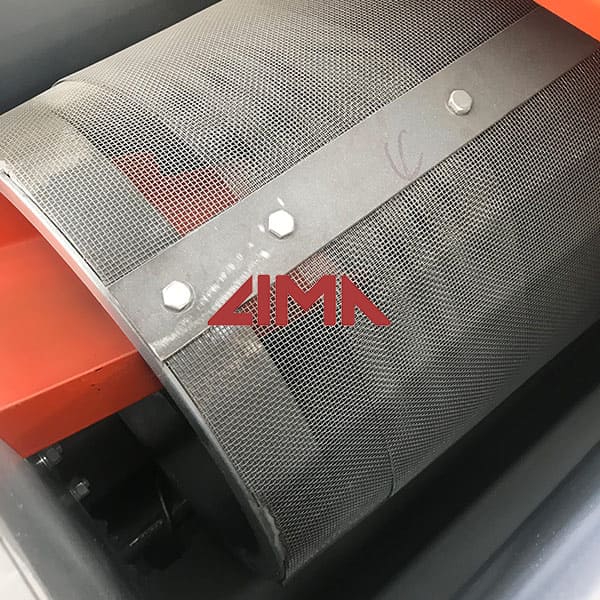

POULTRY AND LIVESTOCK FEED PELLET MAKING MACHINES IN SOUTH AFRICA. We offer the best quality poultry feed pelletizer, this pellet press mill is available on 220v and 380v and can also make wood pellets and other items. 4.00 /5. 1 reviews. Price: R 12.000,00. R 12.000,00. Contact.

There are many advantages in the processing of crop straw into pelleted feed by use of feed pellet making machine: During the feed pelletizing process, the processing temperature can be 800℃~1050℃, can make the starch in the feed produce a certain degree of maturation, and produce a strong fragrance. In addition, pelleted feed is hard and

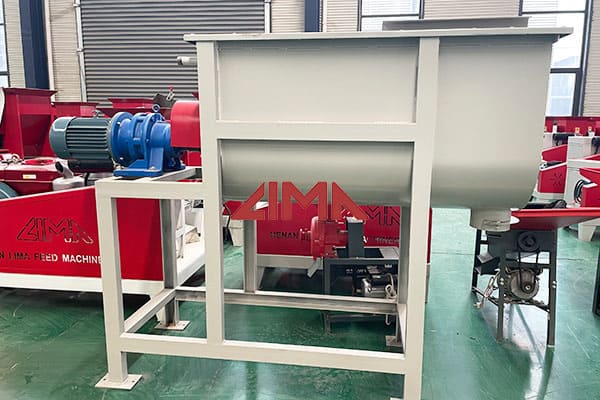

Livestock Feed Processing Plant. Offer customized feed factory layout design with moduel designed livestock feed processing machine. Start you feed manufacturing business from making high quality livestock feed pellets with ABC Machinery's innovative machine. The advanced livestock feed processing technology used in ABC Mahcinery's feed plant also help avoid cross contamination efficiently, reduce the production cost and shorten your cost recovery cycle.

Most of imported corns are used for making chicken feed. Green (grass, broad leaves): Green is rich in nutrition and can greatly reduce the costs of feed, and can improve the protein content of animal feeds. As we all know, South Africa is rich in forest resources, it also can improve the energy efficiency. Widely used in making animal feeds.

Chicken feeding line is an automated poultry feeding equipment, mainly adapted to the feeding of broiler, chicken products, finished chicken. With a high degree of automation, accurate feeding control and other characteristics, chicken feeding line is composed of silos, feed pan, conveying pipe, auger, motors and level sensors and other

Estimated cost of plant, delivered and installed: R1,750,000. Payback period: 6.5 months. It is therefore clear that the large scale farmer can save some R270,000 per month for mixing his own feed and an individual entrepreneur may have a lucrative business opportunity in installing an ABC Hansen Mini Feed Mill.

Grinder, mixer, pelleting machine, freezer, sifter, weight scale, packaging bags and more are some of the necessary feed processing equipment for starting a complete cattle feed production factory. Here you can see a 3-5 ton/h cattle feed manufacturing process flow chart. This process and layout was designed for one of our clients in Mali, West