The ideal combination of very high specific torque (up to 15 Nm/cm³) and a large volume (OD/ID = 1.66) in one extruder - this is the feature which makes the ZSE MAXX twin screw extruder stand out. An extremely large range of processes benefits from the maximal adaptability of the ZSE MAXX since it has high process engineering relevance. As a

The Axial Xtruder is a twin screw extruder used to make large extrudates from 2.0- 8.0mm. The extruder converts wetted powders into pellets of a controlled size and shape. Twin screws transport the wet material to the extrusion zone where it is wiped through the perforated axial die plate to produce well-formed cylindrical extrudates of a

The MAS 24 LABORATORY EXTRUDER is the only conical & co-rotating twin screw extruder available for small volume applications. This technology enables the customer to process a wider range of materials including recycled materials on a laboratory scale. It is also ideal for small-scale high-end polymer compounding applications.

The new standard for extrusion excellence. Our latest range of premium equipment for high quality production lines. Evolum+ twin-screw extruders are equipped with advanced technology to give our customers new levels of throughput, flexibility and control while ensuring optimum process stability and maximum food and non-food product quality.

18 MM Leistritz Twin Screw Extruder Pelletizing Line. Manufacturer: Leistritz. Used Leistritz twin screw pelletizing line, model Micro18-GGL, 18 mm screw s, counter rotating screw s, 40:1 l/d, 500 rpm screw speed, electrically heated, water cooled barrel, 2.3 kw, 210/260 volt, 2950 rpm dc mot Cleveland, OH, USA.

Coperion、Milacron、JSW、Shibaura Machine and Leistritzv, ranking among the top 5 take up over 40% of the global market share. In 2020, the global twin-screw extruder market size was $869 million and is expected to reach $1,128.2 million by the end of 2027, growing at a CAGR of 3.8% during 2021-2027. China is the world`s second-largest

The twin screw side feeder for extruders enables the side feeding of fillers and additives in powder or pellet form or cut glass fibers into the processing section of the twin screw extruder. The side feeder features a self-cleaning profile of the twin screws and product feeding into the screw flights of the extruder without stagnant zones.

In the plastic extrusion equipment, plastic extruder is usually called the main engine, and its supporting follow-up equipment is called auxiliary machinery. Plastic extruder after 100 years of development, Extruder has been developed from the original single screw into a twin screw, multi-screw, and even no screw and other models, The extruder can be matched with the

High quality High Torque Lab Scale Twin Screw Extruder / Engineering Plastic Laboratory Scale Extruder from China, China's leading Lab Twin Screw Extruder product market, With strict quality control Lab Twin Screw Extruder factories, Producing high quality High Torque Lab Scale Twin Screw Extruder / Engineering Plastic Laboratory Scale Extruder products.

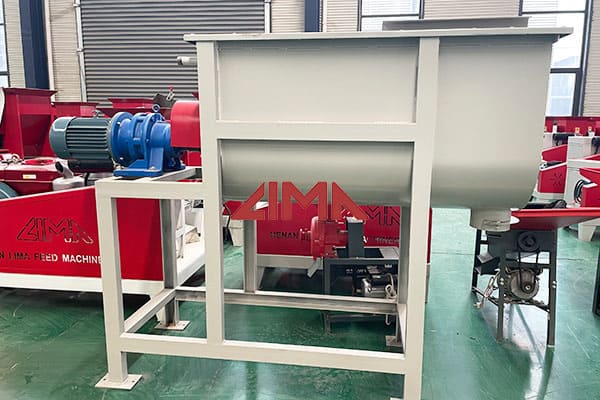

Animal Feed Pet Food Extruder Different Capacity Large Scale CE High quality Animal Feed Pet Food Extruder Different Capacity Large Scale CE Certification from China, China's lead + 86 19337889085 . sale@limamachinery.com large scale feed

Requiring only a small amount of material to conduct experiments, labscale extruders allow you to conduct numerous trials efficiently, cost effectively, all

2021-11-25 · The technical feature of the twin-screw extruder is the use of twin-screw extrusion technology. It is the most popular and effective technology in pet food, aquatic feed, puffed snacks and soy tissue protein production industries. Twin-screw extruders adopt a couple of paralleled and joggled screws to push raw materials forward. The screw is

China Extruder Screw Twin manufacturers - Select 2022 high quality Extruder Screw Twin products in best price from certified Chinese Machine Screw, Extruder Machine suppliers, wholesalers and factory on Made-in-China.com

2019-07-22 · In recent years, single-screw extruders have developed greatly. At present, a large-scale single-screw extruder for granulation in Germany has a screw diameter of 700 mm and a yield of 36 t/h. The main sign of the development of single-screw extruders is the development of its key component, the screw. In recent years, a large number of