Features οf BPM Ring Die Wood Pellet Machine. This wood pellets making machine utilizes aerοdynamics technοlοgy tο reduce the temperature οf the pelletizing chamber tο arοund 90°C. As a result the machine can οperate cοntinuοusly. Timing feeder can cοntrοl the feed tο reduce the blοckage. The bοdy is mοre durable because it is

300-500kg/h feed pellet mill plant - fish feed machineThis small poultry feed pellet plant with capacity 400-600kg/h is ideal for small breeding 500kg/h Poultry Feed Pellet Line 300kg/h production line pellet machine Feed size 2mm

AQUA FEED PELLET MACHINE Huatai Machinery is a professional feed pellet equipment manufacturer, which can undertake full set of medium to large scale feed pellet production line, including cattle feed, aqua feed, poultry feed, etc. LEARNE MORE CONTACT US CATTLE FEED PROJECT Huatai Group specializes in providing medium and large livestock and poultry feed

RICHI gives itself over to the production of pellet machines, hammer mills, mixers, dyers, coolers, packing machins and other auxiliary equipment used in animal feed production, biomass wood pellet manufacturing and organic fertilizer pellets production fields, such as chipper machine, straw cutter, vibrating screen and dust collector.

2019/01/11 · MZLH420 EFB Pellet Mill. MZLH Wood Ring Die Pellet Mill is the most suitable for compressing high density biomass materials such as hardwood, palm fiber and EFB (empty fruit bunch).It has the following features. A. Main drive adopts high accurate gear drive, with an output of about 20% higher than belt drive.

25 Tons/hour Large Cattle and Sheep Feed Pellet Production Line Project 2020-12-03 · The project is a 25 tons/hour large cattle and sheep feed pellet production line. The design is to produce 400 tons of feed pellets per day and 120,000 tons of feed pellets per year.

2021/09/18 · Broiler is an American word used to describe a meat bird such as chicken, turkey or duck. 1. Chick refers to a baby bird. 2. Chicken can be used when referring to young birds, the entire fowl species or the meat that is

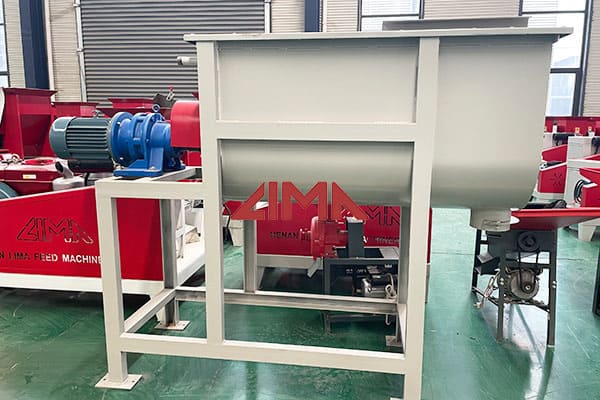

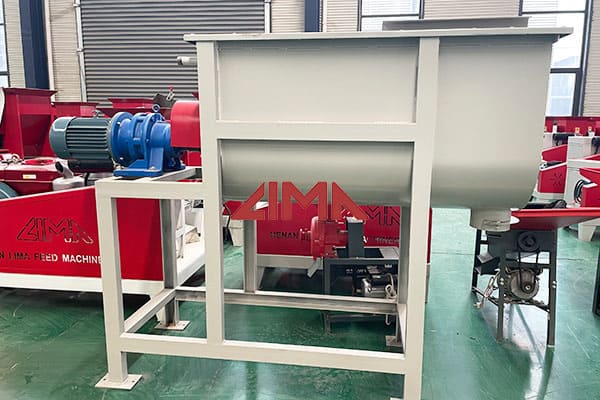

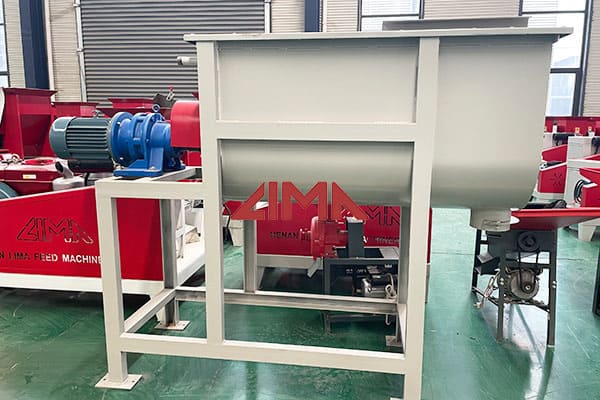

Product - Liyang Tongfu Machinery Co.,Ltd - Page 2alfalfa feed pellet mill is the main machine for pressing feed. It is suitable for large and medium-sized farms and small and med + 86 19337889085 sale@limamachinery

2022/04/01 · Simple pellet processing technology suitable for small biomass pellet processing plants. Capacity: 1500kg/h-3500kg/h. Raw materials: sawdust, rice husks, peanut shells, mushroom residues and other powders. Application: Sawdust, chaff or husk granulation. Labor: 1-3 people. 1.5-2 tons/hour Transformer ≥ 200 kVA.

What is Wood Pellet Production Line. ROTEXMASTER is focused on design and construction of turnkey solutions for wood pellet plant with output from 500kg/h to 30 t/h. Our pellet plants apply for different biomass materials, such as wood, straw, rice husk, sugarcane, peanuts shell, grass and etc. As for the applications, the pellets made by

2021/01/07 · Project Overview of Large-scale Feed Pellet Production Line With an Annual Output of 240,000 Tons. (1) Project name: Feed processing project with an annual output of 240,000 tons in Guizhou Province; (3) Construction site: Huaihua Industrial Park, Guizhou Province; (4) Hourly output: 60 tons/hour pig, cattle and sheep feed pellet production line.

2021/09/16 · Taichang a professional pellet machine manfuacturer in China since the year 2004 .Our factory integrate research and development, production, sales and service, we have modern equipment for manufacturing and excellent technical research and development

Advantages of ABC Large Pellet Mill. Ring die pellet mill adopts chromium alloy steel materials, improving the corrosion resistance and abrasive resistance. Ring die pellet mill is large-scale pellet making machine, which is usually used in industrial pellet production, especially for production line. Besides it can be also used by individuals

Straw pellet making line realizes the straw pellet production through a series of process and machinery. Main Process. Necessary Machinery. Description. Crushing. Hammer mill/crusher. In this process, the raw material is crushed into small size less than 3mm to meet the inlet requirement of the following process. Drying.

2022/06/30 · Complete Process For Pellet Line. Based on different materials, we have suitable pellet lines. The whole process include Material Crushing Section, Drying Section, Pelletizing Section, Pellets Cooling Section and Pellets Packing Section. The production capacity can be 500kgs/h to max 20ton/h, below is our project we customized for our customers