Feb 14, 2022 · Floating Fish Feed Machine Price, 100-500KG/H Sunwit Fish . Advantages of Sunwit Fish Feed Machine. Fish food made by this pellet extruder is of puffing type, more easily to digest for fishes. The fish feed pellet size can be from 0.9-10mm to feed different sizes of fishes. The puffing fish feed pellets can float on the water surface without

These Fish Feed Mash are processed and manufactured by using the quality assured material and advanced techniques. Our presented Fish Feed Mash is highly tested by our professionals on various parameters. It is widely appreciated and demanded in the market. Our company provides the safe and best delivery packaging option. We use the excellent

Floating fish feed pellet machine price diesel engine tilapia Floating fish feed pellet machine is widely used for producing high-grade aquatic feed pellets for many kinds of aqua Tel: +86 173 3777 1729

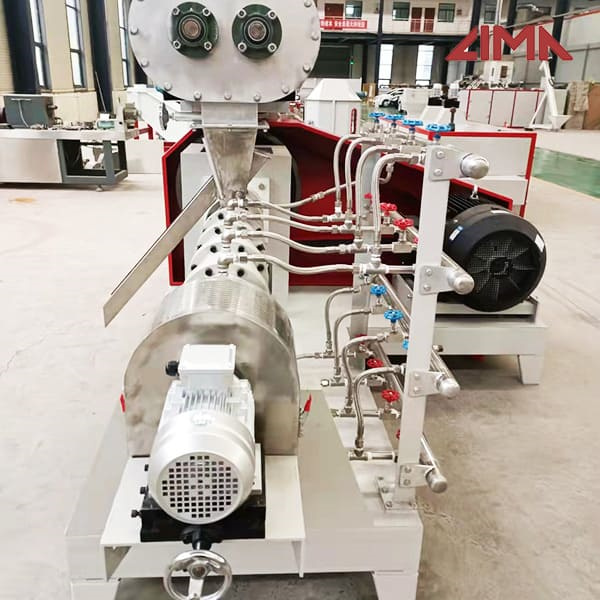

Description. Floating fish feed extruder machine is a kind of fish feed pellet machinery ,it is suitable for small and medium feed process factory and aquaculture farm. It can produce high-grade feed pellets which is suitable variety aquatic ,such as fish, catfish, crab, shrimps,cat,dog etc.Single screw extruder is much cheaper price and easy

Feed Variants. Floating pelletized fish feed is processed in two ways: pelleting or extrusion to get premium fish feed pellet. Click here to preview the fish products we have available. Floating pellets: Floating pellets are loosely pressed when manufactured, thus filled with small air pockets which make them buoyant and easy to float. The

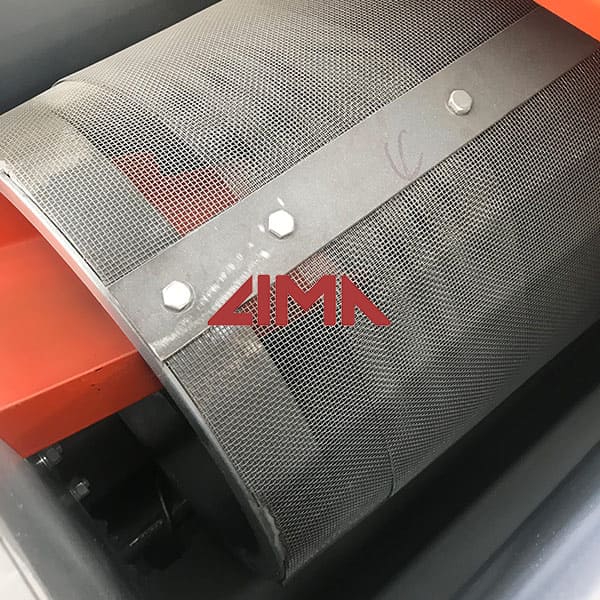

1.The fish feed pelletizer is widely used for producing floating feed pellets of all kinds of aquatic animal, like tilapia, catfish, shrimps, crab etc. 2.Both floating and sinking aqua-feed pellets both can be made just by adjusting feed formulation. 3.Different molds can be chosen to make pellets with different diameters and shapes,size range

Brief introduction of the floating fish feed pellet making machine. From 40kg per hour to 2 tons per hour, our machines have many models with different capacities to meet varieties of customers’ demands. It’s widely applicable to large, medium, and small aquaculture, individual farmers, and small and medium-sized aquaculture use.

Oct 16, 2018 · The final pellets have unique shape and good taste, high nutrition and smooth textures. For feeds of fish and shrimp, the floating time in water can be adjusted by the extrusion degree adjustment. Feed pellets dia. is 0.9-15mm. We have wet type fish feed extruder and dry type fish feed extruder for your choice.

Fish Feed Extruder Features and Advantages. 1.Floating, sinking, and slow sinking aqua-feed can be produced by adjusting feed formulation and related parameters of expansion. 2.The finished pellets can keep floating for 3-15 hours without pollution to water. 3.The machine can make pellet from the diameter of 1.0mm-20mm just by changing the mould.

Sep 10, 2021 · The Utilization Rate Of Puffing Fish Feed Puffed floating fish feed is beneficial to improve feed utilization. Due to the high temperature and high-pressure processing conditions, the starch in the feed is more suitable for digestion and absorption, and the fiber structure and cell wall are damaged and softened, the gospel in the cottonseed meal and the anti-trypsin and other harmful

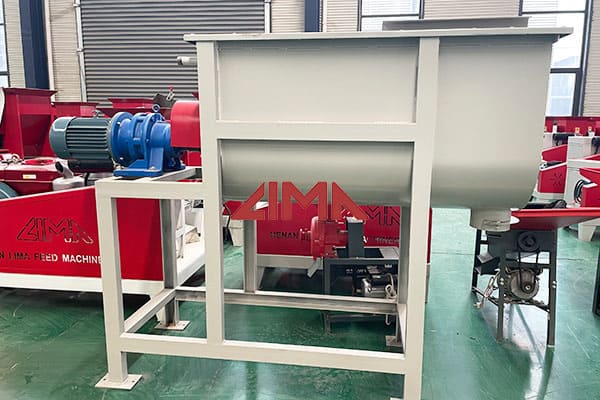

2019/12/18 · Poultry feed manufacturing process flow chart. The processing of composite poultry feed is usually divided into the following steps: receiving and cleaning of raw materials, crushing of raw materials, batching, mixing, pelleting and packaging. The diameter of the final feed pellets can be 2 to 8 mm.

Floating Fish Feed Pellet Plant Fish Feed Extruder Machine2021. 9. 16. · Fusmar Machinery specially customize floating fish feed pellet plant, to satisfy high demands for cost-eff

Mini fish feed extruder is used to produce floating fish feeds at home or for small scale fish farms with low cost investment. It ensures the new investors affordable to the machine, and with 30kg/h production capacity. It is widely used for processing grains powder into high-grade aquatic feed pellets for fish, catfish, shrimps, crab, tilapia etc.

Floating Fish Feed Manufacturing Process. Selection of Raw Material. When selecting raw materials for fish feed processing, remember that the final product must be stable in water. The main nutrients are starch, with 10% to 15% of feed for sunken fish and over 20% of feed for floating fish. The starch content is generally between 5% and 60%.

Reducing feed waste:Floating fish feed has good water stability, floating in water long for several hours, hence avoiding the dissolution of nutrients in the feed and the sinking of feed into the mud, reducing feed waste to a large extent. According to tests, using floating fish feed can save about 10% of feed than using powered or hard pellets