May 14, 2020 · 2.If you want to make pellet feed, the manufacturing process: Cleaning -- Crushing -- Mixing -- Pelleting -- Cooling -- Packing. For pellet feed,the mash feed will go to the following feed processing machine. Animal poultry chicken cattle aqua feed pellet machine will form the mash feed into pellet feed.Usually we use ring die pellet mill for

Effects of feed form and energy levels on growth performance, The birds were distributed according to a completely randomized design in a 2 × 4 factorial arrangement, consisting o

Broilers Feed - Mash (70Kgs) Broiler Starter 142,600 Broiler Finisher 146,600 Layers Feed (70 Kgs) Chick and Duck 153,300 Growers

poultry feed mash plants and pellet feed plants2020. 10. 22. · poultry feed mash plants and pellet feed plants. We design animal feed pellet plant of different capacities for almo

Oct 16, 2018 · The final pellets have unique shape and good taste, high nutrition and smooth textures. For feeds of fish and shrimp, the floating time in water can be adjusted by the extrusion degree adjustment. Feed pellets dia. is 0.9-15mm. We have wet type fish feed extruder and dry type fish feed extruder for your choice.

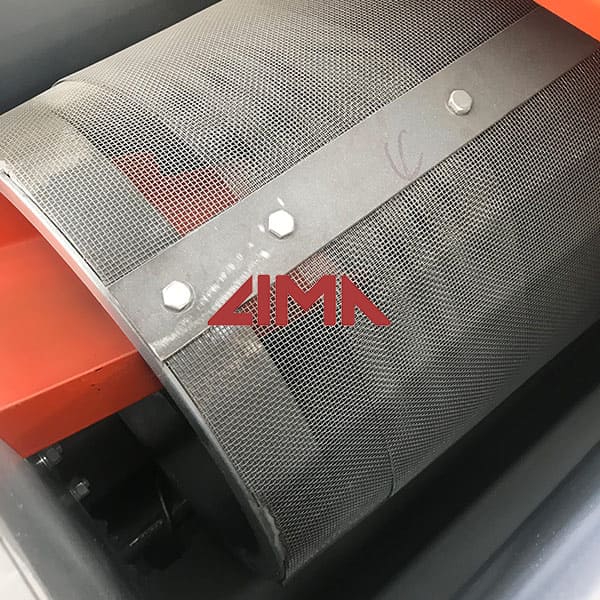

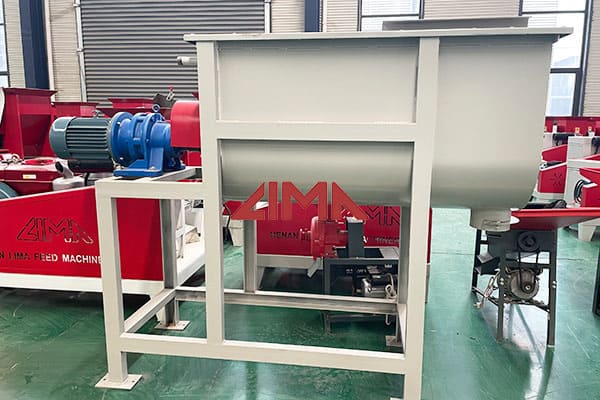

Feed crushing machine Feed Mixing Machine Fish Feed Machine Fish Feed Production Line Poultry Feed Machine Flat Die Poultry Feed Pellet Making Machine Ring Die Poultry Feed Pellet Making Machine Poultry Feed Machine Line Chicken Feed Pellet Line 1-2t Chicken Pellet Line 100-1000kg

fish mash feed machine project australia Australia 1-2T/H Small Scale Chicken Feed Mill Project This Australia 1-2 ton per hour automatic small plant chicken feed mill project is mainly for broiler chicken feed production, because the Australia chicken breeding industry has excellent development prospects.

this type fish feed pellet machine is used to make fish feed pellets which can float on water about 12 hours , the finished pellets can be made from 1 micrometer to 15 micrometers, the fish food pellet machine can also be used to make pet animal food like for dog, cat, and so on, the final food shape for pet animals can be cross type or bone type, also can make chicken food.Extruded fish feed

2022. 4. 8. · MZLH350 Recycled Plastic Resin Pet Pellet Press Machine Project For Korean Market Region: Asia Product type: wood Complete 30,000 tons per year cow sheep dung pellet plant project for organic fertilizer production Region: China Product type: wood Big scale long service life 400,000 tons per year animal poultry livestock feed production plant

Fish Pellet Making Machine livestock grain grinder project australia-Lima Fish Feed Machine. RotogrindRoto Grind Tub and Grain Grinders Burrows Enterprises, LLC ...

Jan 01, 2005 · ground for a mash type finished feed ground for a pellet type finished feed whole grain with a pellet type complementary feed. Wheat energy value is stable regardless of the type of presentation. Whole grain maize shows a 3% lower value, but this may be due to more difficulty for ingestion of grain.

We are a well established manufacturer and supplier of an extensive range of Fish Feed Mash. These Fish Feed Mash are processed and manufactured by using the quality assured material and advanced techniques. Our presented Fish Feed Mash is highly tested by our professionals on various parameters. It is widely appreciated and demanded in the market.

In magnetic separation we have developed cascading magnets of self cleaning design with high cleaning efficiency. LARK can offer Mash Feed Plants of any capacity (say 2 ton/hr – 100 ton/hr or more) with optional auto bagging or auto batching (pre-weighing), single line to multiple lines of grinding and mixing.

This feed pellet plant can produce 2~8mm of feed pellets with 600-1000kg/h pellet output capacity. The pellets are suitable for feeding pig, cattle, sheep, rabbit, chicken, duck, geese, fish and other animals. The grinding machine can crush the maize and soya bean meal into fine powder, then the fine powder can mix with the wheat bran, bone

Pellet mills are not designed to crush or digest blends. It is fed into the pellet mill bin, located above the pellet mill. The mash is fed into the pellet maker by gravity. Gravity feeds the hot, squeezed mash into the cooler. The flowing air cools and dries it for 3–6 minutes. The dust collected by the dust collector is returned to the