Animal feed cooling equipment cow feed pellet cooler machine, US $ 10000 - 10000 / Set, Manufacturing Plant, Retail, Video technical support, Online support, Field maintenance and repair service, Egypt, Indonesia, Russia, South Korea, Bangladesh, South Africa.Source from Jiangsu Liangyou Zhengda Co., Ltd. on Alibaba.com.

The fish feed mills are currently trying to produce soy-based floating fish feed in Pakistan with imported U.S. soybean meal. The feed in Oryza Company is the first of its kind produced in the country. Apart from the soybean meal, some local raw material can be also used to produce floating fish feed.

Aug 26, 2021 · Fish Pellet Machine-Lima Fish Feed Machine May 18, 2021 · Design and production of a fish feed pelletizing machine 23/11/2018 · 2.1. Machine description The important components of the pelleting machine are the hopper where the feed mealis fed into the machineand the pelleting chamber in the form of worm auger or screw shaft which is seen to propel the feed.

Fulll Equipment of 2TPH Livestock Animal Feed Pellet Mill Plant 1. Mixing Machine 2. Screw Feeder 3. Storage Silo 4. Feeding Device 5. Pellet Machine 6. Belt Conveyor 7. Pellets Cooler 8. Belt Conveyor 9. Bagging Equipment

Fish production in pakistan - fish production exceeds 3,200 tons per annum in KP. PTI government has established 28 fish farms in different districts besides provision of 834,800 fish stocking of fry and finger lings (small fish) to farmers during last five months in different districts of the province. +.

Oct 19, 2018 · 5.The cooled feed pellets temperature won’t be higher than ambient temperature + 3~5℃, also suitable for cooling particle material. 6.High cooling speed and favorable cooling effect. The counterflow pellets cooler can cool more pellets while maintaining optimum pellet quality. 7.Lower power consumption, easy operation and cleaning, high

Pelleting by fish feed making machine is an important link in the fish feed production process of pellet feed, which directly affects the quality of pellet feed. Email: enquiry@pellet-richi.com. WhatsApp: +86 138 3838 9622. Get Price & Service.

This customer interested in SFE60C and SFE70B fish feed extruder. His demand is production capacity <250 kg/h and the pellets must float. According to customer needs, This 200kg/h fish feed making set contains: mixer machine, fish feed extruder, pellet dryer and oil sprayer. Photos: 200kg/h small fish feed making plant for Tanzania.

This feed pellet plant can produce 2~8mm of feed pellets with 600-1000kg/h pellet output capacity. The pellets are suitable for feeding pig, cattle, sheep, rabbit, chicken, duck, geese, fish and other animals. The grinding machine can crush the maize and soya bean meal into fine powder, then the fine powder can mix with the wheat bran, bone

Apr 12, 2022 · USDA, along with the American Soybean Association (ASA) and the Fisheries Development Board (FDB), has funded a three year aquaculture project FEEDing Pakistan with an initiative to improve the livelihood of Pakistan farmers and consumers through increased aquaculture productivity. A key component of the project was to conduct soy-based feeding trials on tilapia using pelletized floating fish feed.

Feed Pellet Project Show. We stand behind every feed pellet mill we build, so you can be assured that your feed pellet business is built around a reliable machine.Our feed pellet plant is designed 24/7 working.

There are 3 types of sinking fish feeds machine available for processing sinking fish feed pellets: sinking pellet machine with two-layer conditioner, three-layer conditioner sinking pellet feed machine and sinking fish feed extruder machine. Email: enquiry@pellet-richi.com. WhatsApp: +86 138 3838 9622.

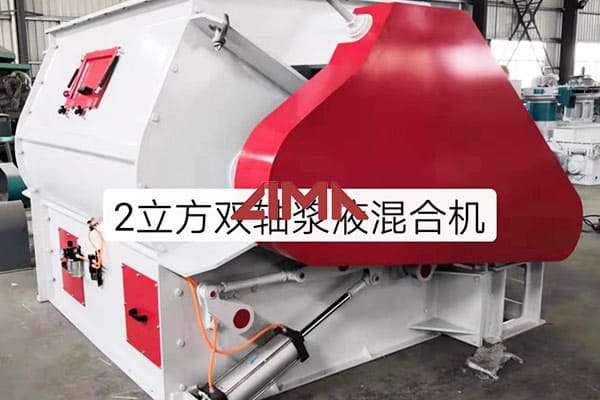

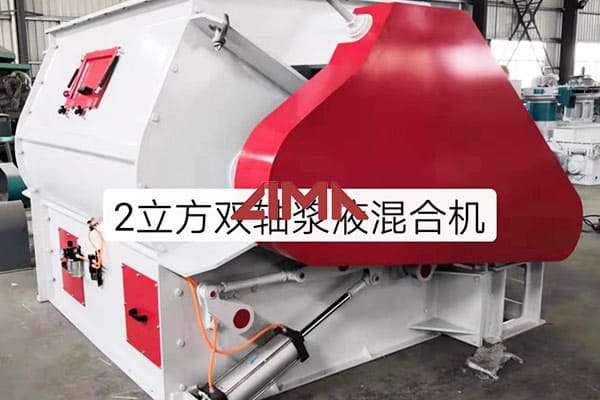

Feed hammer mill crusher: 55: Crush wheat, corn, sorghum and other grains into powder: 2: Double shaft paddle feed mixer: 11: to mix all raw material particles and other powder and additive well and together: 3: Feed pellet mill: 45: The crushed raw materials are made into feed pellets. 4: Feed pellet cooler: 1.5: cooling down the feed to room

Fish Feed Pellet Cooler. This counter flow pellet cooler is widely used to cool finished pellets with high temperature or high humidity. It adopts counter flow cooling theory, and pellets can be cooled completely and evenly through the machine, which is good for the pellet packing and storage. The advantages is energy saving, easy to operate, preferred choice for most users of wood and feed pellets plant.