2019. 3. 17. · enough demand in the area to turn a profit if a corn grinder were built. Financial Plan The corn grinding project would require a loan of UGX 7.8 million. This business is projected to have a Return on Investment (ROI) of over 60%

Since 1919 BAADER is the worldwide leading manufacturer of Fish Processing Machinery and Solutions. BAADER plans, designs and set up complete processing lines.

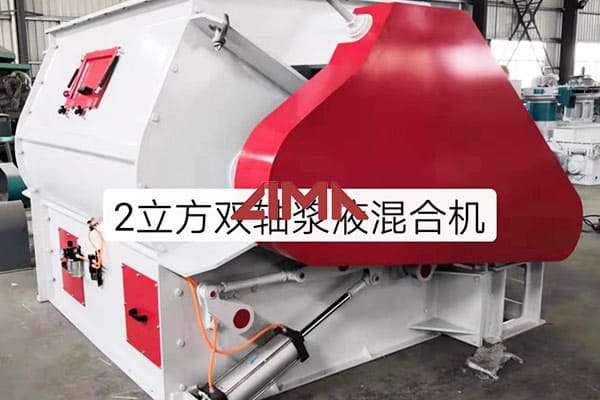

This feed pellet plant can produce 2~8mm of feed pellets with 600-1000kg/h pellet output capacity. The pellets are suitable for feeding pig, cattle, sheep, rabbit, chicken, duck, geese, fish and other animals. The grinding machine can crush the maize and soya bean meal into fine powder, then the fine powder can mix with the wheat bran, bone

Product Information: Feed Processing Machines is also named fish/pet feed extruder, and it is used for processing for dogs and cats (pet food), birds, piglets, frogs, Applicable Industries: Advertising Company, Energy & Mining, Farms, Home Use, Machinery Repair Shops, Manufacturing Plant, Restaurant, Retail

Horizontal hammer mill. Our hammer mill is a high efficiency grinder for size reduction in feed and food processing industries. Generally applied for dry materials with a bulk density of 0.2-0.8 kg/dm³, it convinces through high production flexibility and minimal downtime. Overview Key benefits Product features Applications Services and training.

Apr 25, 2022 · Typical moisture loss through a hammermill when fine grinding for aquaculture feeds is ½ to 2%. Hammermills are generally less expensive to install and operate than pulverizers, typically costing between $250 and $350 per HP for a complete system including the hammermill, feeder, and appropriate air assist system.

Applications of Bone Crushing Machine. ★ Bone Crusher can grind different kinds of animal bones, like pork, cow, chicken, fish bone and so on. The final fineness can be 3-5mm. ★ It is widely used for the product of sausage, ham, meatball, frozen food, salt essence, bone powder, powder soup, pet food, etc. ★ Bone Crushing Machine can be

SKIOLD feed mills are batching plants, usually 1-3 tons per batch up to 5-6 tons per batch, normally with 8-12 batches/h. With a 3 tons batch system, the capacity will be 30 t/h with 10 batches/h. With 4-6 tons/batch, the capacity will be 40-60 t/h. The tendency goes towards more batches/h – up to 15-20.

Our animal feed processing technologies appeal to both commercial feed millers producing for onward sale, as well as to farmers making feed for their animals. Our pelleting technologies enable our customers to create their own unique recipes and combinations of ingredients – making sure that the animals are given

- use of feed per 1 kg of weight gained equal to 2.54 kg - mean body weight of an 8-week old chicken was 1.20 kg - slaughter efficiency higher by 23% - costs of the components used in the feed lowered by 20% - content of additional animal feed lowered by two-thirds, that is, by 110 kg/1 t of combined feed, fish and meat meal, and powdered milk

2. What do fish need in their feed? Fish1 (including prawns or shrimp) need energy and essential nutrients for maintenance, movement, normal metabolic functions and growth. Fish can obtain their energy and nutrients from natural food in ponds, from feed supplied by the farmer or from a combination of both sources.

PELLETING. The transformation of a soft, often dusty feed into a hard pellet is accomplished by compression, extrusion, and adhesion. The general process involves passing a feed mixture through a conditioning chamber where 4 to 6 percent water (usually as steam) may be added.

About 140 Mahoneys Road, Thomastown, Victoria 3074, Australia Phone: +61 3 9469 2023 Email: sales@pacificfoodmachinery.com www.pacificfoodmachinery.com

Liyang Sunrise Machinery Co., Ltd. is a professional manufacturer specialized in designing and making feed processing machine, sunrise company introduces a full set of world-class technology of CNC laser cutting machine, profile automatic sand blasting equipment, automatic paint room, shear bending equipment, specializing in the production of complete sets of feed machinery equipment and turn

Generally speaking, fish feed production process flow has several main steps, including procurement of feed ingredients, raw materials grinding, mixing, extruding, drying and automatic weighing and packaging, in tune with scientific and nutrient aquatic feed formulation. Acquisition of feed ingredients. According to nutritional requirement for