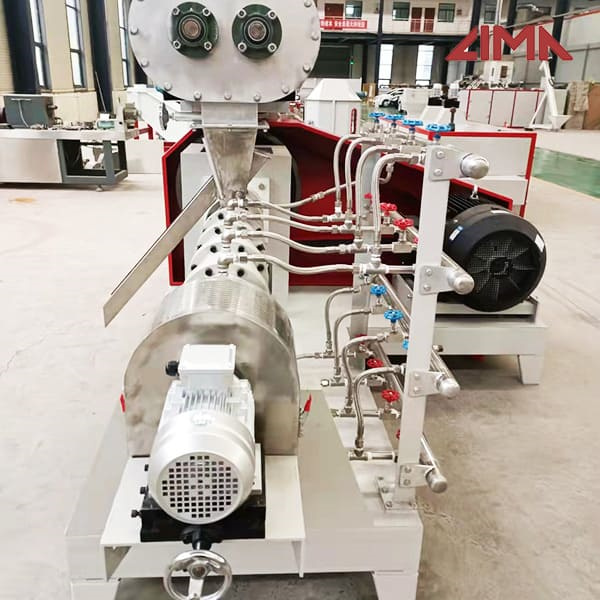

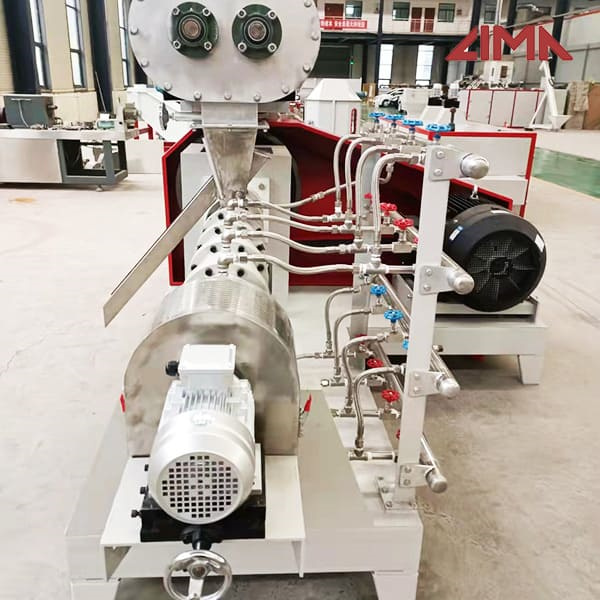

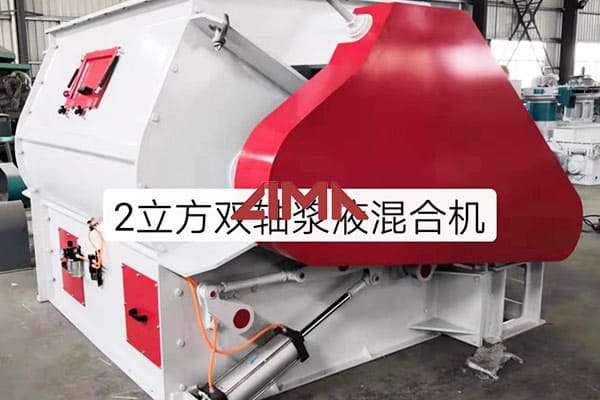

This customer interested in SFE60C and SFE70B fish feed extruder. His demand is production capacity <250 kg/h and the pellets must float. According to customer needs, This 200kg/h fish feed making set contains: mixer machine, fish feed extruder, pellet dryer and oil sprayer. Photos: 200kg/h small fish feed making plant for Tanzania.

A feed mill is a machine that processes ingredients of an animal feed into pellets, which are convenient to transport and store. The ingredients will consist of grains, fats, vitamins, rough fiber, binders, protein, fish meal, bone meal, and others. The mix is designed to provide the intended animal a complete balanced diet for its intended use.

1. To design a crop residue crusher to accept feed materials of corn, millet, wheat and other cereal stovers. 2. To fabricate the designed prototype machine which power rating shall not exceed the 12 kW power upper rating of conventional domestic diesel and petrol engines. 3. To test the performance of the newly constructed machine. IV

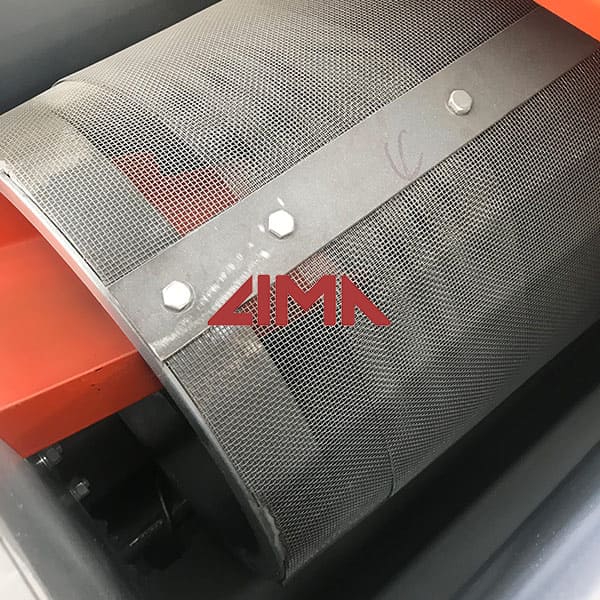

The fish feed making machine was designed to make fish feed,pet feed,and other animal feed,it was taking meat meal, fish meal, bone meal, corn meal, soybean meal, grain flour etc. as the mainly raw materials. by changing fish feed recipe, temperature, molds and others, can produces fish pellet food in different shape,color.taste.The feed pellets produced by our fish feed production line have

It is the desirable or necessary fish feed machine in Nigeria to produce a floating feed to accommodate the feeding habits of the target species in Nigeria. Main Features of Fish Feed Machines. 1. Fish food made by this pellet extruder is of puffing type, more easily to digest for fishes. 2.

Machines for Making Tilapia Fish Feed. Fish feed extruder machine is widely used in making both floating fish feed and sinking feed pellets for aquaculture farms and feed plants. Through the fish feed extruder we can use cheap local raw materials to produce high-quality fish feed, which may save feed costs. Floating Fish Feed Extruder.

We provide floating fish feed extruder to Nigeria at the prices from US$2000 to US$7500, depending on what production capacity the customers choose. By the way, as the fish feed machine expert, we can customize the production capacities according to customers’ requirements.

After choosing suitable formulation, the next crucial thing is mastering the production process of floating fish feed. Mixing & grinding: The main raw materials of floating fish feed should be mixed and crushed before make pellets, so FANWAY recommends the related professional equipment – fish feed mixer and fish feed crusher, aiming at

As the professional Floating Fish Feed Pellet Machine ,our Floating Fish Feed Pellet Machine extruder machine design good manufacturing process. Brand Name:Loyal. Model Number:PFE-65-1 PFE-70-1 PFE-85-1 PFE-90-1 Place of Origin:Shandong China. Certification:CE,ISO9001,SGS,BV.

Nigeria Journal of Engineering Science and Technology Research Vol. 5, No. 2, 2019(96-102) 101 101 3 RESULTS AND DISSCUSSION The Table 1 presents results of performance test of the machine.

Nov 02, 2016 · Nigeria have a big market for fish farming,Our Fish Feed Pellet Machine Exported to Nigeria,if you are looking for how to make floating fish feed,projects of fish feed extruder machine in nigeria,cost of fish

DESIGN AND CONSTRUCTION OF A FISH FEED EXTRUDER 1. I.F. Odesola, * 2. R.A. Kazeem, 3. N.C. Ehumadu . Abstract-In fish farming, the consumption of feeds in pellet form aids the total consumption of the ingredientsby fishes. Nevertheless, some local farmers in Nigeria are using pelletized feeds in their various farms because of the reduced cost.

500 cm3 of starch was added to one part powered using a 3 kW electric motor and was and was thoroughly mixed. tested to determine the output of the machine and 5. The machine was powered and the moist quality of pellets produced by the machine under feed was fed through the hopper varying conditions.

Jun 01, 2019 · The throughput is the rate at which the feed sample fed into the machine is been recovered. This was obtained using Eq. (20). In this work, 3 kg of the homogenous feed mixture was fed into the machine and 2.2 kg of the feed was recovered at a time interval of 8 min. This gave a throughput capacity of 0.275 kg/min, which is approximately 17 kg/h