The pellet cooler has a unique mechanism of cooling, cooling air and high temperature and humidity material reverse motion, make the material gradually cool top to bottom. Avoids for quenching cracking caused by material surface, the moisture in the pellet core evaporates easily, cooling effect is superior to the existing domestic similar products.

2. Powdered feed and grass meal can be pelletized without liquid addition, so the moisture content of pellet feed is basically the moisture content of the material before pelleting, which is more conducive to storage. 3. Chicken, duck, fish feed, etc., can obtain higher economic benefits than mixed powdered feed. 4.

Source Feed crushing machine 5t/h fodder crushing and mixing machine for cow/cattle Feed crushing machine 5t/h fodder crushing and mixing machine for cow/cattle fodder crusher and

Livestock Pellet Machine Cattle Feed Manufacturing Plant Feed pellet machine yield is low The output of each feed pellet machine is not the same, there are many factors causing low output, and there are many factors leading to the decline of its work efficiency, so we have to figure out the reason for processing, so as to get better output, so what are the reasons for the low output

Introduction: This animal feed plant is designed to produce both concentrate flour feed and pellet feed, with capacity 2-3T/H, it is suitable to produce chicken feed, cow feed, horse feed. This cow feed pellet plant includes pulse dust collector, feed grinding machine, and feed mixer, Feed pellet machine, and feed cooler, feed sieving machine

Making cow dung waste into fertilizer granules, it is essential for you to equip with a cow dung manure pellet machine. It is a machine for recycling your waste. Shunxin has pan manure fertilizer granulator machine and cow manure pellet dedicated granulation equipment for you to choose.

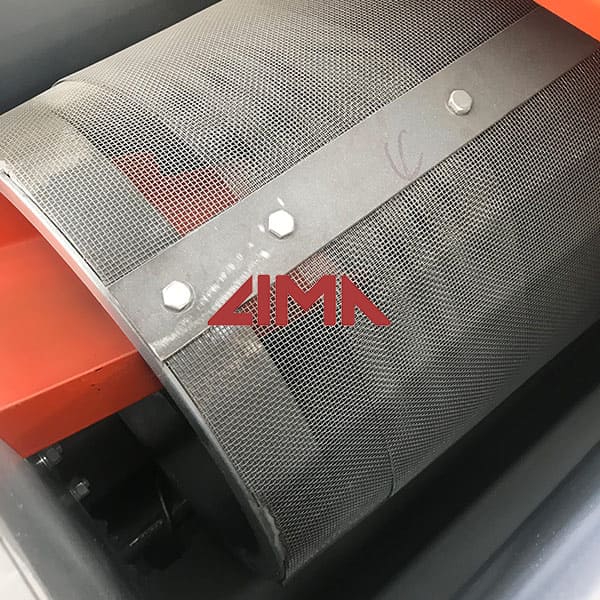

Mar 07, 2019 · Therefore the pellets need to be cooled to remove moisture and heat generated in the conditioning and pelleting. The preferred choice for cooling is counterflow feed pellet cooler which has been the first choice in feed pelletizing plant. 1. Cooling tank adopts octagon design, no dead angles. 2. Large inlet air area, outstanding cooling effect. 3.

Livestock feed pellet cooling equipment Pellet cooler machine2015/10/14 · I. General Introduction to Counterflow Pellet Cooler The counterflow pellet cooler is applied for efficie + 8617337771729

Gear Transmission Cow Cattle Feed Pellet Machine With 6-8mm Feed For Nigeria , Find Complete Details about Gear Transmission Cow Cattle Feed Pellet Machine With 6-8mm Feed For Nigeria,Cattle Feed Pellet Machine,Cow Feed Pellet Making Machine,Goat Feed Pellet Machine from Feed Processing Machines Supplier or Manufacturer-Shandong Double Crane Machinery Manufacture Co., Ltd.

Therefore, different ingredients and nutritious cattle feed pellets are suitable for bulls, cows, heifers and buffaloes. The pellet feed can be well digested to improve the performance of the cattle. 1-2T/H Cattle Feed Production Line in Nigeria. Get Price Now! Cattle Feed Manufacturing Process. Step 01: Raw Materials Reception and Cleaning Process

Vertical Feed Mixers for sale @ Post EquipmentTo discuss a sale or purchase, please contact us online or phone 712-476-4500. Smaller vertical mixer! Penta 4020 left hand flip up d

2022/03/17 · Broiler Feed Prices in Nigeria. The costs of broiler feed in Nigeria have already been listed above. For your convenience, here is the exclusive price list again. Hybrid Feed Broiler Super Starter Mash: N3,000 – N4,000. Hybrid Feed Broiler Finisher Mash: N3,500 – N4,000. Vital Feed Super Starter for Broilers: N3,500 – N4,000.

Oct 19, 2018 · The feed pellet cooler can cool down the hot feed pellets from 80 – 90℃ to about 3-5℃ above ambient temperature. The cool air flow could bring away the moisture around the wood pellets thus make the feed pellets dryer. The capacity of the counterflow pellet cooler varies from 3-20t/h, suitable for cooling feed pellets in large and medium

Cattle Feed Plant Manufacturer in Khanna,Crumbling Machine We are A Khanna, Punjab, based firm Nirvair Enterprises, deal in a wide ambit as Manufacturer, supplier, exporter of ind

Mar 07, 2019 · Brief production process of dairy cow feed pellets. 1. Crushing: crush raw materials by feed hammer mill to get fine grinded ingredients. 2. Mixing:all of the ingredients are mixed in a feed pellet blender for a period of time to get a uniform mix. Then a moist, cohesive mash was obtained at end of the final mixing. 3.