feed lumps and gives a dressed feed into the bin above the pellet mill. A pellet mill is not designed to pellet these materials, let alone the animal stomach to digest them. The pelleting process starts with a bin (Figure 1, Item 1) in which the mixture of mash is stored.

Oct 01, 2008 · The planned output of the new feed mill is 25,000 tons per year, of which the majority will be pig feed (20,000 tons). The remaining 5,000 tons will be split equally between broiler and quail feed.

Treating ForagesProcessing hay for beef cows, especially if it is low quality, high in stems or stalks, or badly weathered, can result in feed savings as high as 10-15%. Other ben Emai: sale@limamachinery.com

Beef Cow Rations and Winter Feeding Guidelines The rations contained in this guide were designed to provide an acceptable level of nutrients required by 1,400 lb. cows with an expected calving date of April 1.

Table 2. Mixes for supplementary feeding a. Urea/molasses (roller drums) First week Second week Third week Water (litres) 100 100 100 Molasses (litres) 100 50 30 Urea (kg) - Prilled 15 15 15 Each mix should last about 30 head for 10 days.

Cost of Living in Philippines - 2022 prices.Summary of cost of living in Philippines. Family of four estimated monthly costs: Php142,746. Single person estimated monthly costs: Ph

Feed Pellet Cattle Cattle Feed Pellet Bird Feed Pellet Making Machine And Cattle Sow Feed Pellet Machine For Sale In Philippines Up to 5 years warranty $400.00-$2,715.00 / Set

There are many advantages in the processing of crop straw into pelleted feed by use of feed pellet making machine: During the feed pelletizing process, the processing temperature can be 800℃~1050℃, can make the starch in the feed produce a certain degree of maturation, and produce a strong fragrance. In addition, pelleted feed is hard and

Pelleting Machine Set. PHP 1,234. For Sale !!! Pelleting Machine Set Call 8631-2046 / 09985811801 for more details. Well used

This feed pellet plant can produce 2~8mm of feed pellets with 600-1000kg/h pellet output capacity. The pellets are suitable for feeding pig, cattle, sheep, rabbit, chicken, duck, geese, fish and other animals. The grinding machine can crush the maize and soya bean meal into fine powder, then the fine powder can mix with the wheat bran, bone

raw materials for this animal feed pellet machine is not less than the national standard of 13%.Differential and universal joint driver is adopted.the feed pellet mill can be driven by electric motor or diesel engine.the use of unique technology can complete the whole process of low-temperature drying, cooling and screening in one passage.

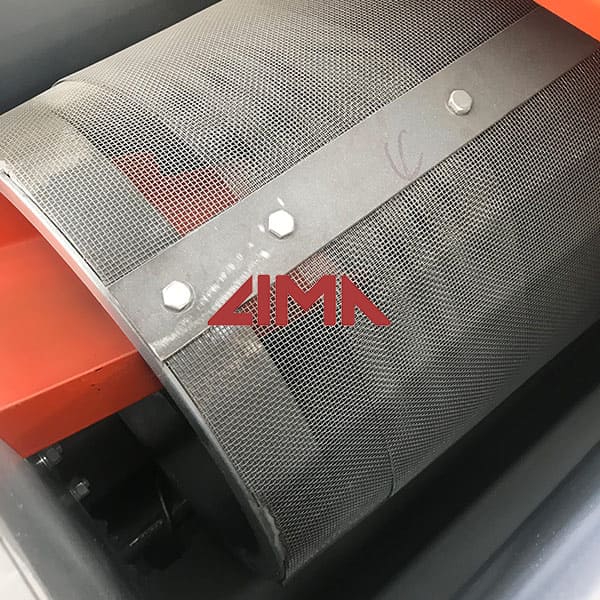

The animal feed pellet mill is mainly driven by the rotation of the die plate to drive the rotation of the built-in pressing roller to quickly squeeze corn, soybean meal, grass fodder, green fodder, etc. into pellets. Feed pellets processed by the commercial animal feed pellet machine can usually be used to feed cattle, sheep, chickens, pigs

Raising an Orphan Calf - Angus Beef BulletinMar 23, 2017 · Many ranchers have raised calves on bottles (an orphan, a twin, a heifer’s calf that isn’t accepted by its mother, etc.

Cattle Feed Machine - Cattle Feed Making Machine Latest Price Call +91-8048962956. Contact Supplier Request a quote. Semi Automatic Cattle Feed Machine, Capacity: 60 To 90 Kg Per

Compared with the flat die pellet machine, the ring die feed pellet machine has a large production capacity. Get Price Now! Step 05: Feed Pellets Cooling Process The feed pellets are produced at a temperature of 88 degrees Celsius and a humidity of 17-18%. For cooling, drying and storage, the humidity should be reduced to 10-12%.