Used rubber extruder make Troester, type GSV 60/k-12-18D-m.S., Execution as desired, with or without vacuum Built in 1991, machine was in operation until the beginning of 2010 Feed roller Kpl. new drive with flat gear motor Screw speed max. 62 rpm. Engine power 22 kW Control with PLC and temperature control new on request Extruder similar to

Cold Feed Rubber Extruders - Cold Feed Extruder Machines Find here Cold Feed Rubber Extruders, Cold Feed Extruder Machines manufacturers, suppliers & exporters in India. Get conta Emai: sale@limamachinery.com

Zhauns Machines. Browse through the available manufacturing machines by category or price, and get in touch for more information. Made from food-grade industrial stainless steel Fill from 2000 bottles per hour Fill glass or plastic bottles Fill water, juice, oil etc.

JRD offers range of cold feed rubber extruder in screw sizes 60 mm, 75 mm, 90 mm, 120 mm. (09) Rubber Cold Feed Extruder Machine Price: 400000.00 Onwards INR/Unit.

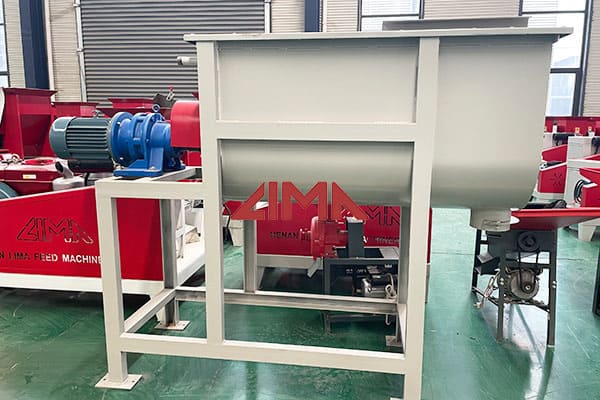

poultry feed extruder low cost in pakistan cattle feed milling machine cost in pakistan-Lima Fish Feed 1 ton/h feed milling machine. $10,000~$20,000. 3 ton/h animal feed process company (both making mash feed and pelleted feed) $60,000. 5 ton/h cattle feed process line. $70,000~$80,000. 10 ton/h feed manufacturing plant. over $100,000.

Tips For Improving The Quality Of Cattle Feed PelletsProveg Engineering & Food Processing Private Limited, Pune - Manufacturer of Poultry Incepted in the year of 2006, Proveg En Emai: sale@limamachinery.com

Mixing of 2/3 different layers of compound flowing on different screw flight paths, facilitates high shear uniform mixing that gives you consistency in the homogeneity of the mixed rubber compounds. ViamTek offers Cold Feed Rubber Extruder in Plain Barrel & in Vented as well with multiple sizes 45mm, 50mm, 55mm, 65mm, 70mm, 75mm, 90mm, 120mm

cattle cold feed rubber extruder machine project philippines Extrusion Process : Working, Types, Application, Advantages Sep 25, 2019 · Hot Extrusion: If the extrusion process takes place above recrystallization temperature which is about 50-60% of its melting temperature, the process is known as hot extrusion.

HOT FEED TYRE TREAD EXTRUDER MACHINE . Single Screw cold Feed Rubber Extruder Rubber Machinery Extruder. Rubber extruder machinery is one of the most widely used important equipments. It is mainly used in tire tread, gaskets, tape, and other rubber extrusion.

Davis Standard 2.5" Cold Feed Rubber Extruder. Manufacturer: Davis-Standard; One (1) Used Davis Standard 2.5" 60mm Cold Feed Rubber Extruder, Model 25IN25, 20:1 L/D, 17.28:1 G/B ratio, Reliance 50 HP 1750-2100 RPM 500 VDC motor, DC variable speed drive, straight delivery head on pedestal

NRM Extrusion Rubber Extruders - Davis Standard Extrusion NRM EXTRUSION® RUBBER EXTRUDERS cont. MACHINE DESIGN PARAMETERS* 2 ½ inch (65mm) Extruder Size 3 ½ inch (90mm) Non-Vented + 8617337771729

These Cold Feed Rubber Extruders are ideally used for different types of rubber and sealants. We offer Cold Feed Rubber Extruders in plain barrels in ‘Vented’ & ‘Non-Vented’ designs in 55mm, 60mm, 75mm, 90mm, 120mm, 150mm scroll size for tubes, fire-houses, profiles, tyre treads, bead covering, blanks, slugs, apron-cots, fuel tubes

Feb 24, 2016 · Plain Barrel Type Cold Feed Extruder – These CFE’s as the name suggests have a plan barrel and used in manufacturing of hoses, blanks, fluorocarbon rubber, butyl rubber, etc. Pin Barrel Type Cold Feed Extruder – These CFE’s have around 80-100 pins protruding out of the barrel towards the screw center.

Used machine: Extrusion lines for coating DAVIS STANDARD,SENFENG - 2012. COEXTRUSION (3) COATING & LAMINATION LINE DAVIS STANDARD-ERWEPA Machine composed of: Main Unwinding with Splicing Unit Corona Pull Roll Station 1 Primer Coater & Dryer 3 Extruders (with QSE Adapter, extrusion Down Pipe, Cloeren EBR Die, Gravimetrics 3+1) Auxiliary Unwind with splicing unit shafted design Laminator Edge

Browse similar products RUBBER MACHINE; I. Name: Rubber Extruder, Cold Feed Rubber Extruder. II. Features: 1. Front Barrel: Outer barrel is made of high quality carbon steel; Inner bushing adopts 38CrMoAlA high quality nitriding steel, quenched and nitrogen treatment, surface hardness HRC65-70, hard layer depth 0.5-0.7mm; Bushing outer diameter of the ring is formed with an annular groove for