Feed Milling. Satake design and build feed milling plants for poultry, livestock and aquaculture feed production. Plants can be designed to produce pelleted or mash feed and include all the equipment necessary for a ‘turnkey’ solution. Many of Australia and New Zealand’s largest feed mills have been built by Satake.

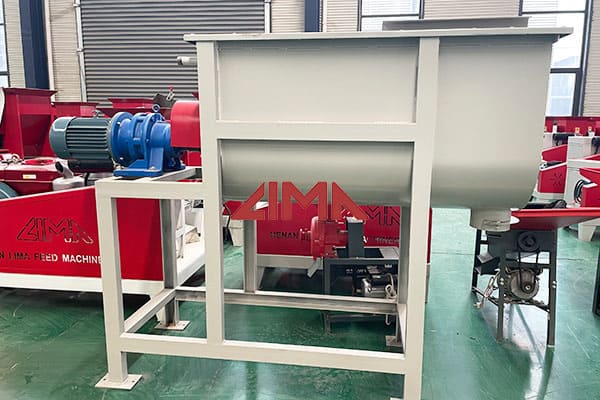

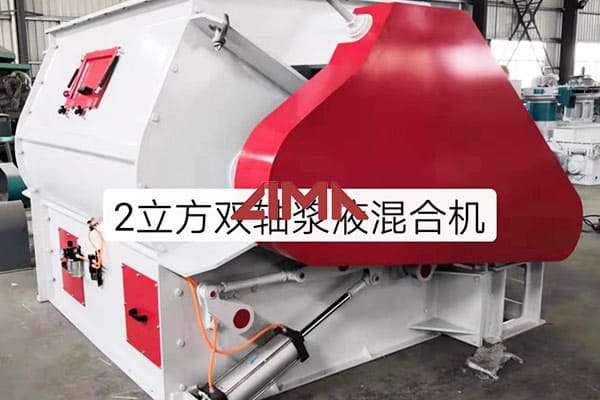

1. Chicken mash feed production process. If you want to make chicken mash feed, the chicken feed manufacturing process: Cleaning -- Crushing -- Mixing -- Packing. Generally,we can divide the raw materials into two parts:one need to be crushed,the other need not.So when we feed material to the feed production line,we will first separately feed

2019. 5. 16. · Poultry feeds are commonly classified into three according to their appearance. They include: 1. mash type. 2. pellets type. 3. crumbs type. The most popular for an average small scale poultry

Jan 01, 2005 · ground for a mash type finished feed ground for a pellet type finished feed whole grain with a pellet type complementary feed. Wheat energy value is stable regardless of the type of presentation. Whole grain maize shows a 3% lower value, but this may be due to more difficulty for ingestion of grain.

Apr 22, 2020 · Laying mash is a grain-based feed with ingredients such as bone, meat scrap and limestone that give hens extra vitamins and minerals. To produce eggs, hens need enough calcium, protein and minerals for their bones and body functions, and then enough excess nutrients to create the eggs. Is laying mash good for chickens?

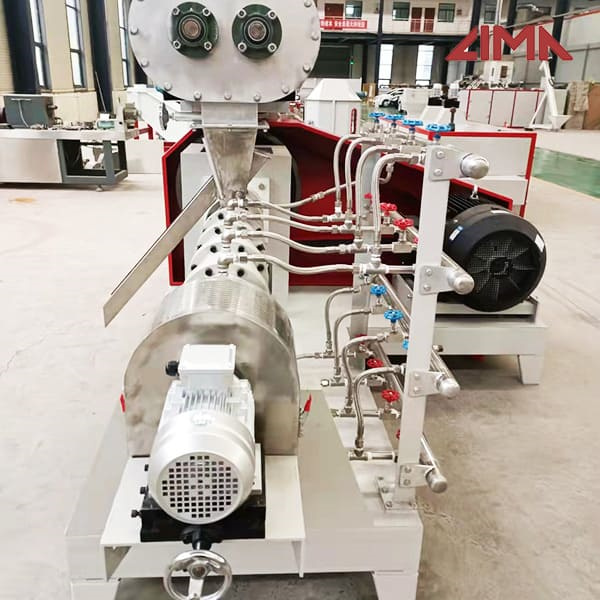

Oct 11, 2018 · For chicken feed pellet mill with flat die design, we have two kinds of driven engine, one is electric motor, the other is diesel engine. Which engine to choose, just depend on you local condition. Among all these flat die feed pellet mill, AZSPLM-260B feed pellet mill is our hotsale one, as it has medium capacity 400-600kg/h.

The mash feed should be replaced with mixed feed (mash feed and pelleted feed) in appropriate time to ensure the development of chicken’s digestive organs. 55%~85% of the poultry feed should be at the size of 1~3mm. Feed milling project for your reference: 2 ton/hour Animal Feed Processing Machine. For the chicken before the litter, the feed

Jun 26, 2020 · Crumble. In simple terms crumble is a coarse variety of mash but not as compact of pellets. Reminiscent of the texture of oatmeal, crumble is a semi-loose variety of chicken feed that is slightly easier to manage than mash. Some chicken lovers use crumble to bridge the gap between mash and pellets for their flock.

Dec 18, 2019 · Poultry feed manufacturing process flow chart. The processing of composite poultry feed is usually divided into the following steps: receiving and cleaning of raw materials, crushing of raw materials, batching, mixing, pelleting and packaging. The diameter of the final feed pellets can be 2 to 8 mm. This is a multi-functional feed pellet making

Nov 24, 2017 · The downside to mash is that waterfowl have trouble swallowing mash without added water. Therefore their tendency is to take the mash to water, wasting feed in the process and usually leaving quite a bit of feed in the water. Pellets Pellets start as a mash that has steam added and is compressed into its pellet form.

Jan 27, 2022 · 18 to 20% protein; 16% protein if heritage or pastured. As a general guide, take a closer look at the ingredients list and nutritional content in commercial poultry feed to get an idea of what percentages to aim for. You will need to balance all the macronutrients (fats, carbohydrates, and protein) and micronutrients (vitamins and enzymes).

Leaders in today’s poultry growing industry need every benefit available to them to gain and retain a competitive edge. From design of the farm and building of the sheds, silos and feed systems to feeding and processing the stock, intensive farming practices have the need for quality engineered products that are purpose built to deliver superior serviceability and fit the requirements of

Some our bulk chicken feed includes: Reid Chick Start – as the name intends, this feed is intended for freshly hatched chicks until they reach six weeks of age. Reid Chick Grower – this feed is ideal for chicks who need the additional protein and energy required for growth between 6 and 12 weeks of age. Reid Pullet Developer – once your

The way that a chicken’s feed is manufactured plays a large role in what the feed turns out to be. Both pellets and crumbles are derived from ‘mash’. Chicken mash is made up of crushed grains, protein (ground mealworms) and meal supplements. It is designed to be a complete feed that is often fed to young chickens because it is smaller and