For daily rations to support 10 chickens, you’ll want to mix together 10 cups wheat berries, 5 cups peas, 5 cups oats, 4 tablespoons sunflower seeds, and a cup of mealworms. If you’re pre-mixing, combine two parts wheat berries to one part peas in one bin.

Low Cost Animal Machine Animal Feed Manufacturing Machine Best Sale Low Cost Animal Poultry Pellet Feed Manufacturing Machine 500 Kg/h Feed Mill Plant $5,000.00-$25,000.00 / Set 1.0 Sets (Min. Order)

Fish Feed Making Machine; Low Cost Pellet Mill; Chicken Feed Making Machine like Manual Slipper/Hawai Chappal Sole cutting machine, H type power press, C type ...

A chicken pellet making machine can be used to make pellets for cattle feed, pig feed, chicken feed, horse feed, duck feed, fish feed and even rabbit feed. The machine comes in different sizes depending on the intended feed production capacity it can be as low as 50 kg/hour to above 1 tonne/hour. And, different die diameters allows to make the

Semi-automatic chicken cutting machine, 300-500 kgs per hour Semi-automatic chicken cutting machine, 250kg, 1 hp; Dice automatic chicken cutting machine, for poultry packing,... Semi-automatic automatic frozen chicken cutting machine, 500... Automatic chicken cutting machine, 600 kg per hour, 3 hp; Dice semi automotive chicken cutting machine, 150 kg per hou... Automatic chicken cutting machine, 2 hp; Chicken cutting machine, 1 hp, 150 kg/hr

May 13, 2020 · These are:-. 1. Fats. Chicken use fats for energy since fats have high energy density. A type of fat known as linoleic acid is known to improve on the egg size. Chicken need between 3% to 5% fat in their feed. 2. Carbohydrates. Chicken require energy for all the activity, growth and production.

Production Output Range: 1~1000,000 tons/year. ABC Machinery supplied poultry and cattle feed plant adopts module design which can realize customized feed processing plant. Meanwhile, as an experienced feed mill machine factory, we can also help you make the best business plan for setting up your own animal feed pellet plant, like mini poultry

9/47 industrial area kirti nagar, Kirti Nagar industrial area, New Delhi - 110015, Delhi. Star Supplier TrustSEAL Verified. Company Video. View Mobile Number. Call +91-8048955571. Contact Supplier Request a quote. Poultry Meat Processing Plant, 240v, Capacity: Barco ₹ 4 Lakh. Get Quote. Chicken Processing Plant, Model Name/number: Barco

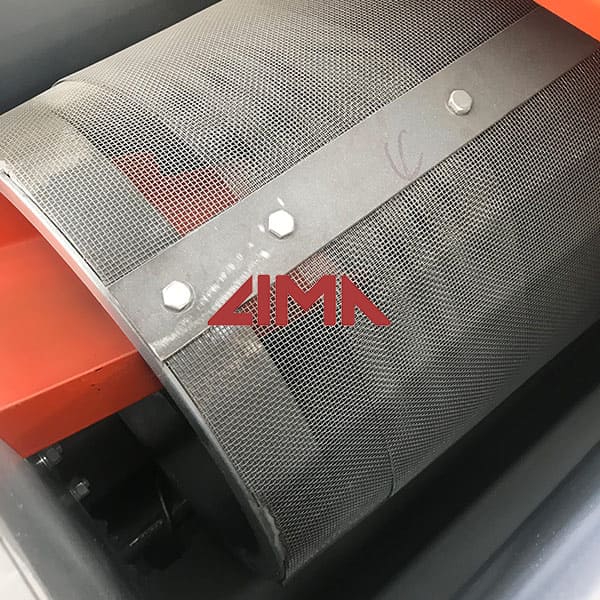

Made of stainless steel, reasonable structure, and reliable. Specifications: Model YYJ400-II YYJ600-II. Belt width 400mm 600mm. Belt speed 3~15m/min adjustable 3~15m/min adjustable. Flattening thickness 3-30mm adjustable 3-30mm adjustable. Power 1.5kW 1.5kW. Overall dimension 2135×715×1320mm 2135×915×1320mm. Request.

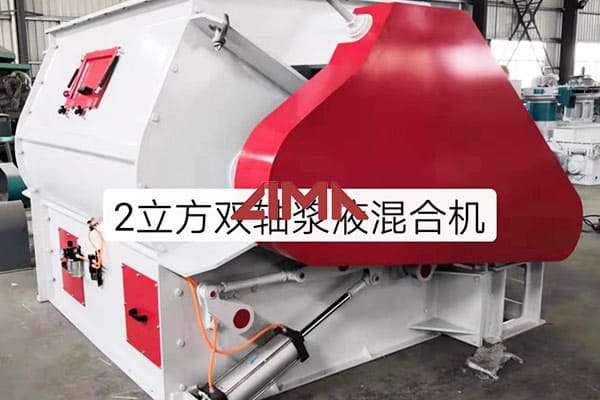

The flat mold granulator is the first choice for breeding farms and professional households to reduce the cost of breeding and improve economic efficiency. The production capacity is 100-500 kg per hour, and the small set consists of a pulverizer, a mixer, a screw conveyor, a regulator, a flat die granulator, a rotary screen and a cooler.

Jan 19, 2019 · But I submit this crazy notion: The idea of a perfect diet for chickens is likely the by-product of production farmers looking for the highest egg-laying yield. Lay pellets — A nutritionally balanced feed pressed into bite sized pellets. Lay crumble — The same type of feed, but in smaller “crumbled” pieces.

Chicken Feed Making Machine Cost. For instance, just like our 120 type flat die chicken feed making machine, it costs less, you can take it home with only ¥2000. The 120 type feed making machine can produce 60-100 kg feed pellet for an hour, easily meeting the demand of farmers who requires small production capacity.

India Business Directory - Online business & companies directory with free business listings of indian companies, exporter importer and detailed information about their business profiles.

Maintenance of Chicken Feed Pellet Machine. For new chicken feed making machine, you need to clean the machine after each use. After 15-20 times, the cleaning steps can be omitted. The pellet making machine should use the supporting power according to the instructions. If the power is too small, it will result in low yield and poor effect.

Personal die cutting machines can cost anywhere from $40-$500 or more speaking from the low end to the high end. Typically however manual die cut machines are usually in the $75-$250 price range whereas electronic or digital ones are a bit more.