Pellet size is from 1.5-8.0mm 8-20T/H --- Chicken and Cattle Poultry Feed Pellet Production Line Dimension 12(L)*12(W)*25(H) m Capacity 8-20 T/H Final Pellet Size 1.5mm to 8mm Information This line can make poultry feeds and livestock feeds, also can make powder feeds and pellet fees.

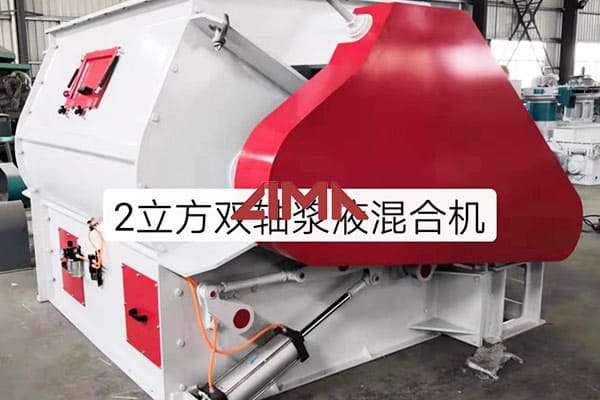

Features of Cattle Feed Pellet Making Machine: 1. Horizontal tank body, need small space but more capacity. 2. Dual screw structure-The inner screw push the material form central to sides and the outer screw push the material from sides. to the center to make the material effective mixing.

Operation guidance for using cattle feed pellets making machine. Step 1 Connect the receiving tray with the pellet machine. Step 2 Add gear oil before starting the machine. Step 3 Connect the motor wires of the feed pellet machine. Step 4 Check if the rollers are loose. Step 5 Add materials to make pellets.

GUIDE TO MANAGING RISKS IN CATTLE HANDLING - Safe Work Australia3 ULY 2016 GUIDE TO MANAGING RISKS IN CATTLE HANDLING Who Duties Designers, manufacturers, suppliers and importers + 8617337771729

2.Determine the feed process and recommend cattle feed machine. 3.Control mode selection. 4.cattle feed manufacturing plant structure selection. 5.Planning the general drawing of cattle feed mill plant site. 6.We devote ourselves to undertaking all cattle feed production line 1-100 T/H.

STLP300 for Mini Feed pellet Mill Plant (600~800kg/h) To start with; STLP 300 is a complete set of poultry / cattle feed making machine that utilizes a power of 45.7 kW, handles a feedstock of 600kg/hour to 800kg /hour on average (best choice for mini feed pellet manufacturing production)

Grinding & Pellet Making Equipment. We offer two pellet mill sizes: HB100 7.5 kw (10 HP) HB 200 15 kw (20 HP) Make your own pellets from just about any material — alfalfa, hops, grass, wood, hemp, municipal waste (MSW), algae, biomass etc for use as feed, fuel, fertilizer, litter or anything you require.

The animal feed pellet mill is mainly driven by the rotation of the die plate to drive the rotation of the built-in pressing roller to quickly squeeze corn, soybean meal, grass fodder, green fodder, etc. into pellets. Feed pellets processed by the commercial animal feed pellet machine can usually be used to feed cattle, sheep, chickens, pigs

Pellet Making Machine. Get Best Quote. Approx. Price: Rs 65,000 / Piece Get Latest Price Product Brochure.

animal feed pellet machine for sale Philippines,Australia 2021/04/14 · animal feed pellet machine for sale Philippines,Australia,Nigeria,Bangladesh,South Africa,India We are speci + 8617337771729

Step 01: Raw Materials Reception and Cleaning Process. The first stage is to receive and clean the raw materials such as grains, beans, forage or fishmeal used to make pelleted feed. Step 02: Feed Crushing Process. These materials are then fed into the hammer mill where it is ground into a size suitable for the production of feed pellets.

C attle feed pellets are a kind of compound feed and mainly made from various raw materials such as, cereals, seed from oleaginous crops and legumes, forage and dried beet pulp and additives, such as, vitamins, minerals, chemical preservatives and other essential micro-ingredients by cattle feed pellet making machine.They are formulated according to the type of cattle.

Note that there are various designs of feed pellet making machine, the type of pellet mill purchased should be confirmed by the scale ,small or large,animal, raw materials at which you intend to produce the pellets. Different livestock have different nutritional needs ,consult a nutritionists ,they will help come up with the right raw materials.

Chicken Pig Cow feed mixer feed pellet machine feed processing machinesyou can contact my email fairy@htoilmachine.com or WhatsApp+ 86 13797445872

Wood Pellet Making Machine for Sale Australia. The 2T/H biomass wood pellet plant was built in Geelong, Victoria, Australia and successfully completed in 2012. The raw material was the mixture of softwood and hardwood, while softwood takes a proportion of 90%. The required production capacity was 1.5-2ton/h. Get Price