2.Determine the feed process and recommend cattle feed machine. 3.Control mode selection. 4.cattle feed manufacturing plant structure selection. 5.Planning the general drawing of cattle feed mill plant site. 6.We devote ourselves to undertaking all cattle feed production line 1-100 T/H.

Description. Feed pellet crumbler is used for crushing big pellet into small pellet, and also crushing materials such as soybeans, corn and soft minerals to reach ideal crumbling effect. Big pellet are pressed and cut into small granular material by the rollers running with different speed,0.6-1.5mm or 1-2.5mm serration particles are available.

Pellet Crumblers. We are Manufacturer, Supplier & Exporter of Crumbler Rollers and our setup is situated in Miraj, Sangli, Maharashtra, India. A crumbler is a roller mill with rolls specially designed for breaking up pellets into smaller particles. Usually the crumbler consists of two corrugated rolls situated below the cooler / drier exit.

Feb 09, 2017 · The Graf Equipment crumbler is designed for crumbling pellets and size reduction. The crumbler is ideal for multistage grinding systems. A robust design, with high throughput and low energy consumption makes the crumbler to a reliable partner in your plant. The crumbler is equipped with two rollers with adjustable distance, and with different flutings to meet customer needs. The feeder ensures

Oct 11, 2018 · Cattle feed pellet is an all-in-one pellet form feed made by feed pellet mill through great pressure. It is a kind of feed that is not only for oxen, cows, cattle but also for sheep, and goat reared for their milk and meat. It contains protein, minerals and other nutrients which are useful for beef and milk production and survival of the animals.

Khare Agromech started its business with a humble beginning in 1989 as poultry and cattle feed machinery manufacturers. As we progressed ahead we developed skills in organic fertilizer machinery, pellet mills and spares for poultry and cattle feed as well as biomass. Since 1989 we have progressed with the active support of our valuable customers.

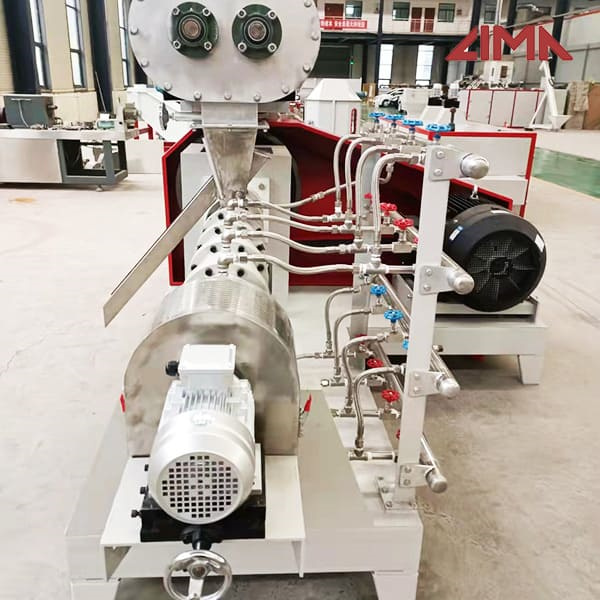

3. Feed Pellet Mill We have five models of ring die broiler feed processing plant designs for your choice. This ring die broiler feed processing plant design is the key part of the complete cow fodder manufacturing plant .

Home » Blog » Fish Feed Machines » animal pellet crumbler design malaysia feed pellet crusher crumbler for animal feed pellets and in usa Feed Pellet Crusher Application The roll type feed pellet crusher is designed to break large feed pellets into small ones of 0615mm or 125mm with rollers equipped with different teeth Roller diameter and

Cattle & Gaot Feed. FOB Price: 200 ~ 210 / Metric Ton ( Negotiable ) Get Latest Price Min Order: 1000 Tons Supplying Ability: 25 KG & 50 KG BAG Business Type: Manufacturing No. of Employees: 1-5 Tags: Goat Feed.

cattle pellet crumbler project sanjivani wenzimiaoshu Feed Pellet Crumbler - Turnkey Project Feed Mill Plant Solutions 2021/04/02 · Description. Feed pellet crumbler is used for crushing big pellet into small pellet, and also crushing materials such as soybeans, corn and soft minerals to reach ideal crumbling effect.

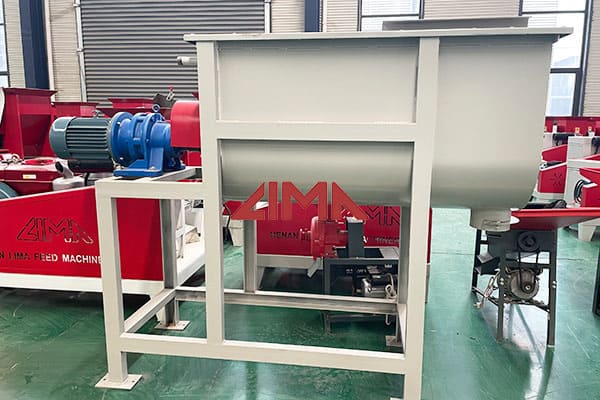

RICHI can undertake 1-100t/h cattle feed pellet production line and provide more value-added service to all the customers (different output configuration can be customized). The main machines of cattle feed pellet production line is cattle feed pellet machine, feed hammer mill, feed mixer and others. *1-12mm pellet size can be choose , we also

Crumbling is the process of breaking pellets in small pieces by passing these through rolls rotating at different speeds having grooves on surface. After the hot pellets are cooled to the ambient temperature, the pellets may require breaking into small pieces to feed day-old chicks and grower flock. Crumbler is equipped with gap adjustment

Wholesale animal feed pellet crumbler Manufacturers & Suppliers, China wholesale animal feed pellet crumbler wholesale animal feed pellet crumbler manufacturer/supplier, China who + 8617337771729

Pellet Crumbler Machine, 12-15 tph. Thanks for Contacting Us. The product offered by us is widely used by the clients as it saves energy and power. It also avoids difficulty in producing small pellets. These products are highly demanded by our valued customers for their easy usage, easy maintenance and durability.

Galen et al. (2000) pointed out is a limitation to the use of the livestock feed that pelleting feeds produced many traits desired pelleting machine because of the high cost of by livestock producers which include decreased the equipment for pellet processing (FAO, 1997; feed wastage, reduced selective feeding, Kabuage et al., 2000; Eugene, 2002).