The Goliath dehairing machine is a ‘single-room’ machine equipped with a heavy-duty scraper roller. Two pigs or one sow can be processed in the machine during each dehairing cycle. A continuous flow of water and a spiral conveyor ensure that hair and nails are automatically removed via a perforated collection channel at the bottom of the

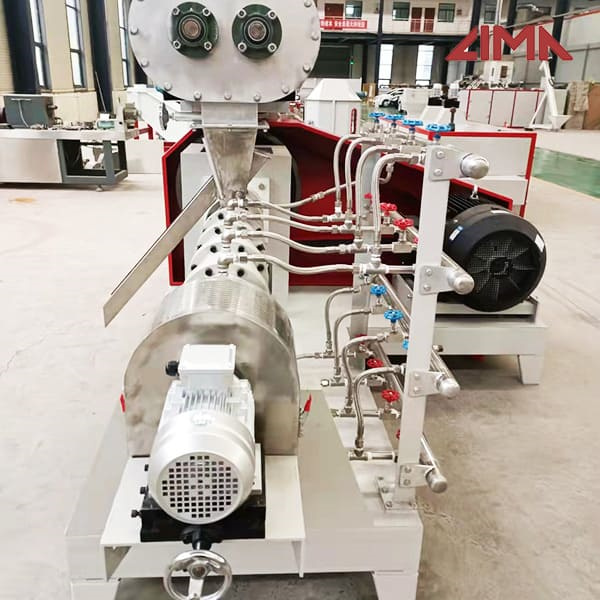

The parts th at make up the livestock feed. pelleting machine are the frame, barrel, hopper, screw conveyor or auger, die, pulley and motor. The machined components were made of mild. steel

Since 2003, Lakidis Food Processing Machinery, with its dynamic export presence, has been developing a global trust network in more than 22 countries around the world, through the equipment of top representatives of the food processing industry.

2008-CEED Seminar Proceedings Lai: Design guidelines of food processing plant 31 3.2 Preview of fresh food processing plant As outlined in the project brief, Homestyle requested for a 3D representation of the new processing plant. To do this, CAD drawings of machines and robots were needed and obtained from manufacturer.

Australia Ethnic Food Machine And Food Processing Equipment Solutions. Our food equipment solutions for clients from over 108 countries. You can click on the following categories to view cases. Each case shows how ANKO conducts food machine solutions - from the beginning of ingredient preparation, machine design and manufacture, troubleshooting

AgTrader.com.au has 71 Feed Mixing & Milling items available for sale and a total of 2825 farm machinery items listed. Choose from Feed and Grain Mixers . From popular makes including Begin, Jeantil, Minos, Penta and more. TopAd Listings. Get Price Automatic Mawa Making Machine Cattle (Steam Boiler Based)

Products and solutions. Marel products and solutions help meat processors optimize yield, quality, throughput and other critical factors across the whole value chain. Ranging from individual units for specific processes such as weighing, cutting and labeling, to complete solutions such as deboning, trimming, meat preparation, portion-cutting

1 ton/h feed milling machine. $10,000~$20,000. 3 ton/h animal feed process company (both making mash feed and pelleted feed) $60,000. 5 ton/h cattle feed process line. $70,000~$80,000. 10 ton/h feed manufacturing plant. over $100,000. Note: When it comes to project investment cost, you need to consider raw materials, workshop rent, equipment

The machine was also tested to evaluate its performance. The machine consisted of a screw conveyor, die, barrel and hopper. It can be driven by an electric motor or a prime mover. The machine was tested with broiler’s mash and at different levels of moisture content using 500, 750 and 1000 cm3 each of water and starch binder as preconditioners.

As specialists in meat and food processing technologies, Ross Industries helps its customers improve the processing, quality, and safety of their food products. Ross Industries has built an international reputation as the engineer, manufacturer, and marketer of the world’s finest food processing systems. All Ross systems are designed to help

2020/05/08 · Feed Mill Design Services Dwight Kinzer, dba Process Equipment & Design LLC specializes in the Process Flow Diagrams, Master Planning, 3D & 2D CAD Layout, and Program Management of Animal Feed Production Plants. Get Price FEED AND BIOFUEL FEEDING AND FUELING THE PLANET feed, animal feed, pet food, and biofuel.

Jun 23, 2021 · In what is claimed to be a world-first off-take-agreement, CH4 Global will provide Australian company, Pirie Meats, with an Asparagopsis seaweed supplement for up to 10,000 head of cattle, cutting methane emissions by up to 90%. The raw material will be cultivated by CH4 locally in South Australia where the company has signed a partnership

the processing facility should be designed, constructed and maintained to ensure that it • accommodates the operations to be performed • provides access to other handling facilities and production pens • minimises stress and bruising on cattle • maximises cattle welfare and worker safety • addresses appropriate conditions for cattle and

From raw material intake to finished feed pellets. ANDRITZ is one of the very few companies with the ability to design, manufacture and supply each and every key processing machine in the feed production line, as well as designing and building the process plant as a whole. Wherever your feed pelleting plant is located and whether you produce

Abstract. Until comparatively recently manufacturers have concerned themselves almost exclusively with the mechanical design and operational requirements of food processing equipment and have tended to neglect hygiene considerations. Equipment should be designed and constructed so that cleaning, maintenance and inspection are facilitated.