ABOUT US. Pellet Technology USA, LLC (PTUSA) was founded at its research center in Gretna, Nebraska in 2012 to deliver high-quality feed products to the animal agriculture industry, packaged to conveniently meet animal's nutritional needs. The company began commercial production in 2014 in Gretna, Nebraska and then in 2016 at the York, Nebraska

1 ton/h feed milling machine. $10,000~$20,000. 3 ton/h animal feed process company (both making mash feed and pelleted feed) $60,000. 5 ton/h cattle feed process line. $70,000~$80,000. 10 ton/h feed manufacturing plant. over $100,000. Note: When it comes to project investment cost, you need to consider raw materials, workshop rent, equipment

It has strong adaptability to the working site, solid structure, beautiful appearance and long service life. In order to improve the production efficiency, in addition to feed pellet machine, some auxiliary equipment for cattle feed pellet production are also needed to form complete cattle feed plant, including hammer mill, mixer, cooler, screw

Namdhari Industrial Works, a ISO 9001:2015 Certified Company, based in Khanna, Punjab, (India) is a manufacturer, supplier & exporter of Cattle Feed Pellet Mill, 6 tph at the best price. We are offering best quality Cattle Feed Pellet Mill, 6 tph to our clients.

Feed pellets can save man power One worker can feed about 28 sheep with fodder ,he also need clean the feed left by sheep that they don’t like.If with pellets feed, one worker can feed 36 sheep and with just less residue .So the labor efficiency can increase 28.57% by pellets feeding. Advantage of Animal Feed Pellet Mill

Peoples Moss Gin Co., Inc. 219 Railroad Avenue Palmetto, LA 71358 Telephone: (337) 623-4294 Toll-Free: (800) 424-4439 Contact: Lynn Coulon

Thomas Moore Feed Mill. 7963 Allen Farm Rd. Navasota, Texas 77868. Phone: 936-825-2239. (Mailing and Physical address)

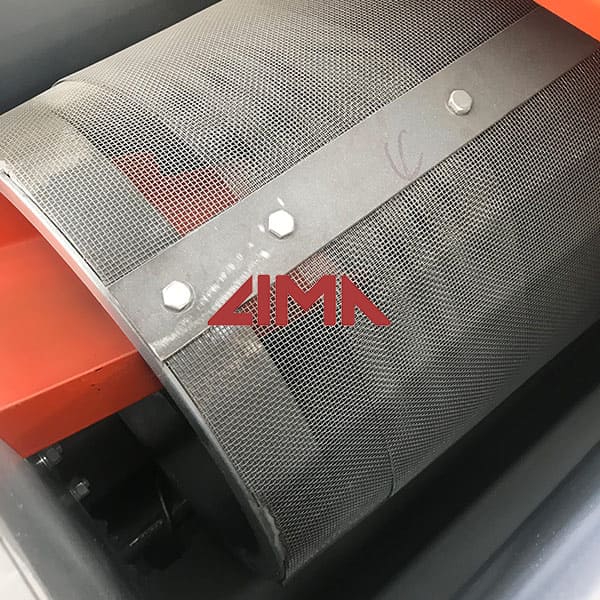

motor-driven pellet mill for animal feed production. The designed pellet mill is composed of major parts like feed hopper, pelleting chamber, pellet roll, die plate, discharge chute, and frame. It is driven by a 1.5 Hp electric motor. It operated using a roll-type extrusion press to force the formulated feeds out of the die plate.

Oct 11, 2018 · Cattle feed pellet is an all-in-one pellet form feed made by feed pellet mill through great pressure. It is a kind of feed that is not only for oxen, cows, cattle but also for sheep, and goat reared for their milk and meat. It contains protein, minerals and other nutrients which are useful for beef and milk production and survival of the animals.

Feed Mill Design Services Dwight Kinzer, dba Process Equipment & Design LLC specializes in the Process Flow Diagrams, Master Planning, 3D & 2D CAD Layout, and Program Management of Animal Feed Production Plants. dwight dot kinzer @ gmail dot com 620-951-4211

Moore Horse 12-5 Pellet; Moore Horse – 12% Horse & Mule Sweet; Moore Horse Alfalfa Pellets; Cattle. 2:1 Breeder Meal; 3:1 Range Meal; 20% All Natural Pasture Cubes; 12% All Natural Cubes; Show Moore Starter/Grower – Medicated; 12% Bull & Heifer Developer; Sweet Grower; Cattle Mineral; All Stock Feed. 12% Easy Keeper Pellets; 14% Horse

All Stock 12 Pellets; All Stock 10 Feed; Cattle. Calf Starter Feed Non-Med; Creep & Fitting Feed; Calf 14 Pellets; Complete Cattle Feed; Instant Milk Replacer 25# Cowboys Range Cubes; Wrangler Range Cubes; Beefmaker 60 Pellets; Super 30 Free Choice Supplement; 24% Cattle Supplement Blocks; 30% Excel Tub; EQUINE. Paradigm Performance Horse Feeds

Sep 01, 2019 · pellet mill off if there is no flow to the bearings. There is also a pressure-relief device in the system that is normally set to operate at approximately 4 Bar. Figure 3-2. Circuit lube system in a gear-driven pellet mill. Lubrication Gear-driven pellet mills are now fitted with integrated circuit lube systems (see Figure 3-2),

Practically 1 MT of material requires 5-6 square feet of area at 15 feet stacking height on maize density. For example: if we have to store raw material stock for 2 months and our daily production is around 100 MT we need ; 100 x 25 days x 2 = 5000 MT of storage for 5000 MT storage on maize density we need minimum space of 28,000 – 30,000

These Pellet Mills are NOT recommended for wood. Click here for wood Pellet Mills. Wood Pellet Mills vs. Feed and Fertilizer Pellet Mills. Take a look at our Pellet Mill/Hammer Mill Combination Deals! (Click Here!) Note: 220V 1ph electricity is a standard in most residences. Most electric ranges as well as electric clothes dryers utilize 220V