One sack cost Ksh. 3,800. Ksh. 11,400. Finisher mash. The chicks consume up to a total of 6 sacks. Each sack holds 70 kg of feeds. Price of one sack is about Ksh. 3, 700. Ksh. 22,200. Cost of Rearing 100 Broilers In Kenya.

Using this estimate, seven to nine bags of 50 kg broiler finisher feed will cost between 20, 000 – 24, 000 shillings. Hence, for feeding, you should budget between 44, 000 – 55, 000 shillings. It should be noted that a proper blend of all these feeds is required for the expected growth of the broilers you are rearing. Drugs and Vaccination

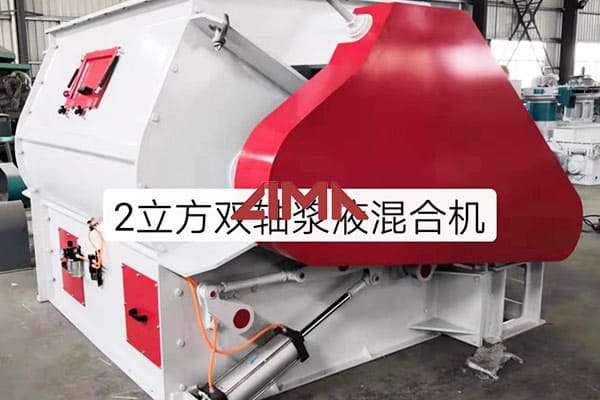

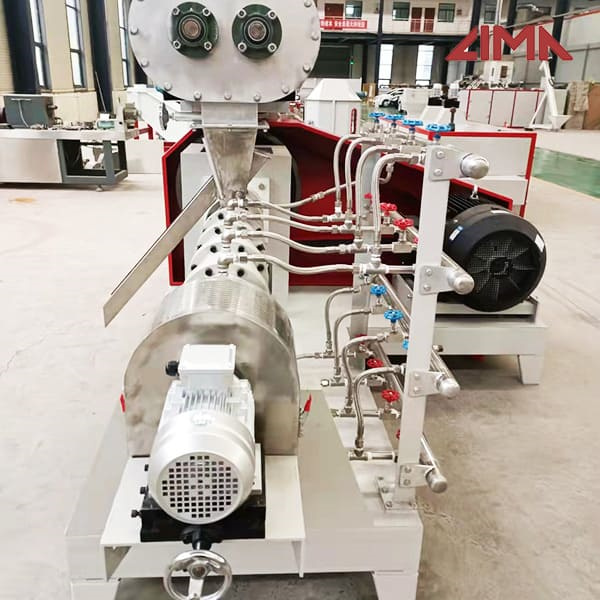

9000. Product description. 1. The screw is made from 38CrMoAIA materials with nitride depth 0.5-0.7mm and hardness HV950-1000. 2. The extruder’s feeding cylinder is composed of a rear body, front bushing and rear bushing. The structure is a jacketed cast iron style. 1. Rear body utilizes cast steel.

Monsanto 150mm Cold Feed Rubber Extruder. Manufacturer: Monsanto Item 6114- One (1) Used Monsanto 6" 150mm Cold Feed Rubber Extruder, 16:1 L/D, 250 HP, 1750/1900 RPM, 500 VDC motor, power feed roll, direct drive, 34.3:1 gearbox ratio, 51 RPM screw speed, Type 3TH 990, S/N 52686

Heidelberg 8 color offset printing machine, sheet fed; Used offset printing machine; Lal used die cutting machines, packaging type: box, automati Prime iso 9001 used paper cup making machine, 1500kg, aut 2009 used ace mcv 450 indian machine, spindle speed: 8000, z... Automatic used 30head computerized embroidery machine

Nov 13, 2019 · 22KW 380V 50HZ. 600-800KG/H. Get Price Now! It has a low production cost: The machine doesn’t need too many people to operate it. In fact, it only takes one or two people to operate it. This significantly reduces labour costs, which greatly affect production costs. Low production costs lead to increased profit margins.

Feb 24, 2016 · The length of a rubber extruder depends on whether it is a hot feed or cold feed extruder. Hot feed extruders are usually very short about 3D to 5D while cold feed ones range from 12D to 20 D . Screws are made of steel alloy forging, heat-treated to a machinable hardness and hard-chrome plated.

Product features: 1.Without warm-up mill for the extruder, investment and production cost can be reduced. 2.Machine optimized screw and barrel design to meet most users requirements of different formulations and different process. 3.The cold feed rubber extruder can equip with different head to extrude different kinds of rubber products.

J. R. D. Rubber And Plastic Technology Private Limited. Model Town, Delhi. K - 49, Model Town, Model Town, Delhi - 110009, Delhi. Leading Supplier TrustSEAL Verified Verified Exporter. Company Video. View Mobile Number. Call +91-8045318834. Contact Supplier Request a quote. 60 Mm Cold Feed Rubber Extruder Machine, 30 Hp.

J. R. D. Rubber And Plastic Technology Private Limited. Model Town, Delhi. K - 49, Model Town, Model Town, Delhi - 110009, Delhi. Leading Supplier TrustSEAL Verified Verified Exporter. Company Video. View Mobile Number. Call +91-8045318834. Contact Supplier Request a quote. 90 Mm Cold Feed Rubber Extruder Machine, 45 Hp.

Product Information. INDEXPELL MAKE Cold Feed Rubber Extruder are suited for High Production, efficiency and eliminate porosity from Rubber Products. No warming mill required as cold rubber can be feeded at room temperature thus saving power and labour and cost of warming mills. INDEXPELL make cold Feed Extruders are designed Rubber Chords

Cold Feed Rubber Extruders - Cold Feed Extruder Machines Find here Cold Feed Rubber Extruders, Cold Feed Extruder Machines manufacturers, suppliers & exporters in India. Get conta Emai: sale@limamachinery.com

A 50 kg broiler starter feed costs between 3, 000 shillings – 3, 500 shillings. One 50 kg bag of broiler starter feed should be enough for a hundred broilers for the period. They might require two bags of growers though. A 50 kg bag of grower feed costs around the same amount as starters, which is between 3, 000 shillings – 3, 500 shillings.

Jun 01, 2019 · The throughput is the rate at which the feed sample fed into the machine is been recovered. This was obtained using Eq. (20). In this work, 3 kg of the homogenous feed mixture was fed into the machine and 2.2 kg of the feed was recovered at a time interval of 8 min.

Mixing of 2/3 different layers of compound flowing on different screw flight paths, facilitates high shear uniform mixing that gives you consistency in the homogeneity of the mixed rubber compounds. ViamTek offers Cold Feed Rubber Extruder in Plain Barrel & in Vented as well with multiple sizes 45mm, 50mm, 55mm, 65mm, 70mm, 75mm, 90mm, 120mm