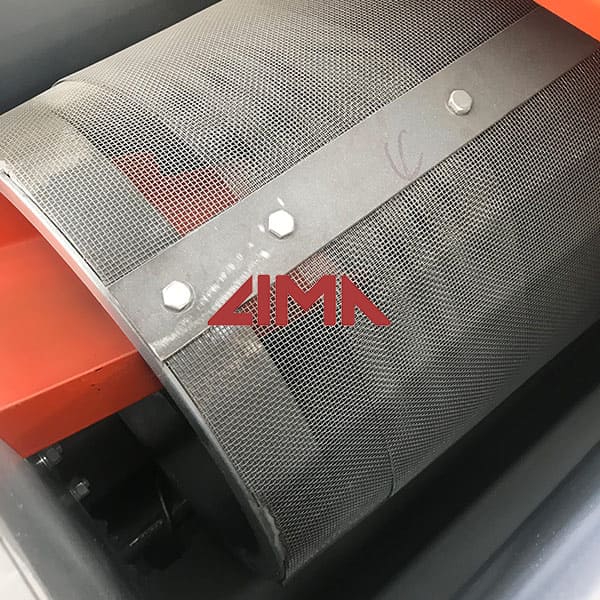

This SSLG series of Pellet Feed Crumbler machine mainly be used for crushing 3-6 mm feed pellet into 1.5-2.5 mm smaller granula feed. It could highly increase the productivity and decrease the energy consumption comparing with directly producing smaller size of feed pellet. Crushing of aquatic pellet feed.

Tons Per Hour Animal Feed Pellet Machine For Making Sheep Feeds Product description Feed pellet machine is widely used in the field of poultry and livestock feed pellet making. Feed pellet mill is the main machine for producing pellet feed and is applicable to large and medium-scaled feed plant with different outputs of pellet feed. This machine

Apr 24, 2022 · The SZLH420 poultry feed production line shipped this time contains 2*1000-ton silos. The whole poultry feed line adopts the production process of first crushing and then batching, and a single poultry feed pellet making machine can produce about 8-12t/h poultry pellets.

Cost per tonne = $300. DM = 90%. ME = 8.5 MJ/kg DM. Cost per kg DM = $300 × 10 ÷ 90 = 33.3c/kg DM. Lucerne hay has an average energy value of 8.5 MJ/kg. Therefore: Energy cost = 33.3c/kg ÷ 8.5 MJ/kg = 3.9c/MJ. At these prices lucerne hay is more than twice as expensive to feed as wheat, even though the cost per tonne is only 50% dearer than

The pellet cooler is mainly used for reducing the pellet temperature and moisture content. 5.Pellet Crumbling Process: Different pets eat different sizes of pet food pellets, so the pellet crumbler can make different sizes of pellet you need. 6.Pellet Packing Process: In order to store and transport, the packaging machine is necessary.

Satake have constructed some of the largest pelleting plants in Australia and New Zealand. Pelleting reduces the volume of bulk products and make transport, storage and end-use easier to manage. It can also improve the enzyme activity and compared to mash feed, pellet feed can increase the feed conversion rate by 10% to 20%.

Palmer milling have over 20 years of plant layout experience. Dedicated team of engineering staff with vast experience in feedmilling. Drafting, from plant layout to workshop detail. Spares. Hammers, pins and screens. Pelleting dies, rollshells and shafts. Sieve screens and brushes. Elevator buckets, belts and bolts. Drag conveyor chain and

China 3-20t/H Pellet Feed Crumble Machine, Feed Pellet Crumbler Machine, Find details about China Crusher, Roller-Type Crusher from 3-20t/H Pellet Feed Crumble Machine, Feed Pellet Crumbler Machine - Beijing Herald Commerce Co., Ltd.

Roll type feed pellet crumbler is just the equipment for feed pellet crushing. Double-roll feed pellet crumbler is suitable for crushing poultry feed, such as chicken feed, duck feed and goose feed etc. Three-roll feed pellet crumbler is suitable to crush aquatic feed including fish feed and shrimp feed etc. 6. Feed Pellet Screening and Grading

Solutions for sustainable animal feed production. Our animal feed solutions help you produce top quality feed and to make economical use of your raw materials and energy. As a technology partner with long-lasting experience in the industry, we support you in every aspect of the production of reliable animal feed. Watch video.

Ripple Mill. Satake Australia recently acquired the manufacturing and product support rights to the ‘Ripple Mill’ previously manufactured by Pellet Technology Australia Ltd. The Satake Ripple Mill is a low speed mill for the efficient cracking of palm nuts. Efficiencies of 99% can be achieved by a single pass.

Mar 01, 2020 · Pellets are compact cylinders that hold their shape nicely, making them easy to store and serve. Manufacturing: As we’ll explore below, crumble and pellets are processed using different machines — a crumbler or a pelletizing machine. Convenience: While both pellets and crumble are popular options, they’re convenient in different ways

1. Roller crumbler is special purpose equipment to crumble big pellets into small pellets. 2. Roller crumbler can crumbled pellet into 0.6~ 1.5mm or 1~2.5mm; 3. Roller crumbler is widely used for crushing poultry and livestock pellets . 4. The finished product has smooth appearance and low powder content. 5.

45. 600-1000. 300-500. Feed pellet line is generally consisted of feedstock crumbler, hammer mill, dryer, mixer, feed pellet mill, cooler, packing scales, etc. Tell us your raw material, requirements of capacity and budget for the plant. Then YULONG can design a suitable and specific solution for you. To ensure the success of your business, we

Fish Pellet Making Machine . Contact US . Tel: + 8617337771729 . Email: cattle feed mixer machine for sale australia Position: