Fishmeal is a natural and well-balanced source of high-quality protein. As ingredients in aquaculture feed, fishmeal and fish oil supply essential amino acids and fatty acids reflected in the normal diet of fish. Fish oil is a major natural source of the healthy omega-3 fatty acids eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA).

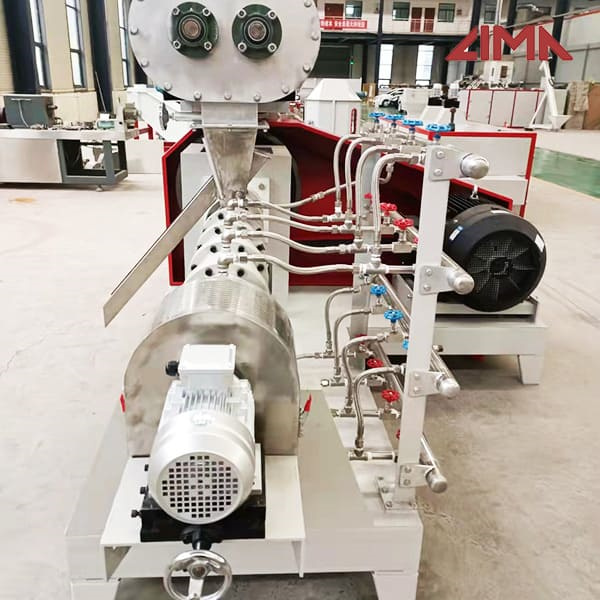

Features of floating fish feed making machine. 1.The cutting device can be adjusted to make pellets of different lengths. 2.High temperature and high-pressure cooking process can kill the salmonellosis and bacterial infections and also makes the pellets easily to digest.

We provide floating fish feed extruder to Nigeria at the prices from US$2000 to US$7500, depending on what production capacity the customers choose. By the way, as the fish feed machine expert, we can customize the production capacities according to customers’ requirements. More specifically, the fish feed production line has capacities with

The feed pellet mill is a feed processing machine that directly compresses the pulverized raw materials such as corns, soybean meals, straws, grass, rice hulls, etc. into pellets, and the process of pellet formation will cause the denaturalization of pancreatic enzyme resistance factors in cereals and beans, which will kill a variety of parasitic ovum and other pathogenic microorganisms, and

Chicken Fish Animal Grass Food Feed Pellet Making Machine Sale In Nigeria: 4: Hot Sale New Design Animal Feed Pellet Making Machine Hot selling in Malaysia 2021 new products Process In Mexico: 5: Pellets feed making machine/extruder for fish feed/chicken feed pellets making machine Sale In United Arab Emirates: 6

Experience – EWOS has been in the aqua feed market for about 80 years, and Cargill has 120 years of experience in animal nutrition. Fish health and welfare – we deliver products that support the overall health of fish. Partnership – we work together with our customers to create mutual success.

Africa Farming Floating Fish Feed Pellet Processing Machine , Find Complete Details about Africa Farming Floating Fish Feed Pellet Processing Machine,Fish Feed Machine,Fish Feed Pellet Machine,Fish Feed Processing Machine from Supplier or Manufacturer-Henan Bedo Machinery Equipment Co., Ltd.

China 2021 motor type fish feed extruder ,it can also kill pathogenic microorganisms and parasites, and ensure the quality of feed. It can be used to raise rabbits, chickens, ducks, geese, fish, pigs, aquatic products, etc. Based on the principle of circular motion, the template and pressure roller are specially treated with high-quality alloy steel.

ral introduction of the float fish feed pellet machine A floating fish feed machine is widely used for producing grains into high-grade aquatic feed pellets for fish, catfish, shrimps, crab, etc.The puffing fish feed pellets can float on the water surface without dissolution for over 12 hours.

This feed pellet plant can produce 2~8mm of feed pellets with 600-1000kg/h pellet output capacity. The pellets are suitable for feeding pig, cattle, sheep, rabbit, chicken, duck, geese, fish and other animals. The grinding machine can crush the maize and soya bean meal into fine powder, then the fine powder can mix with the wheat bran, bone

Figure 1 Exploded view of the fish feeder machine. The machine was designed with the aim of automating the feed metering rate and time spent. on spreading of fish feeds on the pond. Compon ents of

The fish pellet made by the machine can float on water more than 24 hours. Gelatinization degree can reach 90%. Brand Name:Loyal. Model Number:PFE-65-1 PFE-70-1 PFE-85-1 PFE-90-1 Place of Origin:Shandong, China. Certification:CE,ISO9001,SGS,BV. Min.Order Quantity:1 set/Floating Fish Feed Machine.

Fish Feed Pelletizer Machine Price - Price of Fish Feed. 2021 - 04 - 12. We provide floating fish feed extruder to Nigeria at the prices from US$2000 to US$7500, depending on what production capacity the customers choose. By the way, as the fish feed machine expert, we can customize the production capacities according to.

Aug 01, 2021 · The fish feed mixer was produced by putting to play standard design procedures and effective material. The mixer runs with a 1.5Hp, single-phase electric motor and has a production capacity of 50 kg/h. Simulation of the mixer was conducted using a maximum test load of 6kg (equivalent force of 58.86N) of the mixture.