Name:pellet making machine Application:Poultry Farm Raw material:Wheat Bran Capacity:300-500kg/h Color:Clients’ Requirement Function:Producing Animal Feeds Pellets Material:Iron Motor:Chinese Brand Product name:Animal Feed Pellet Plant Usage:Animal Poultry Livestock Pellet Making Machine

his Floating feed extruder for pet feed Making Machine is widely used for producing maize flour, soybean flour or compound powder, wheat bran into high grade aquatic feed pellets for fish, catfish, shrimps, dog,.cat etc. 2 The puffing feed extruder for pet feeds can float on the water surface for over12 hours without water polution.

It is the desirable or necessary fish feed machine in Nigeria to produce a floating feed to accommodate the feeding habits of the target species in Nigeria. Main Features of Fish Feed Machines 1. Fish food made by this pellet extruder is of puffing type, more easily to digest for fishes. 2. The fish feed pellet size can be from 0.9-10mm to feed

Diesel engine fish feed extruder is driven by a diesel engine and operates on this basis. The capacity is from 30 kg/h to 2 tons per hour. It is most favoured by African customers, such as Nigeria, Kenya,Uganda, because of the lack of elctricity in their locals. Cheaper than Motro driven ones. Contact Us Now! Fish Feed Pellets Extruder in Nigeria.

100-200KG/H Simple Fish Feed Production Line. Get Price Now! 300-600KG/H Fish Feed Production Line. Get Price Now! 0.5-4T/H Fish Feed Production Line for Sinking and Floating Feed. Get Price Now! Single Fish Feed Extruder Machine. We have two types of fish feed extruder, dry type and wet type model fish feed machine.

China 2021 motor type fish feed extruder ,it can also kill pathogenic microorganisms and parasites, and ensure the quality of feed. It can be used to raise rabbits, chickens, ducks, geese, fish, pigs, aquatic products, etc. Based on the principle of circular motion, the template and pressure roller are specially treated with high-quality alloy steel.

The fish pellet made by the machine can float on water more than 24 hours. Gelatinization degree can reach 90%. Brand Name:Loyal. Model Number:PFE-65-1 PFE-70-1 PFE-85-1 PFE-90-1 Place of Origin:Shandong, China. Certification:CE,ISO9001,SGS,BV. Min.Order Quantity:1 set/Floating Fish Feed Machine.

his Floating feed extruder for pet feed Making Machine is widely used for producing maize flour, soybean flour or compound powder, wheat bran into high grade aquatic feed pellets for fish, catfish, shrimps, dog,.cat etc. 2 The puffing feed extruder for pet feeds can float on the water surface for over12 hours without water polution.

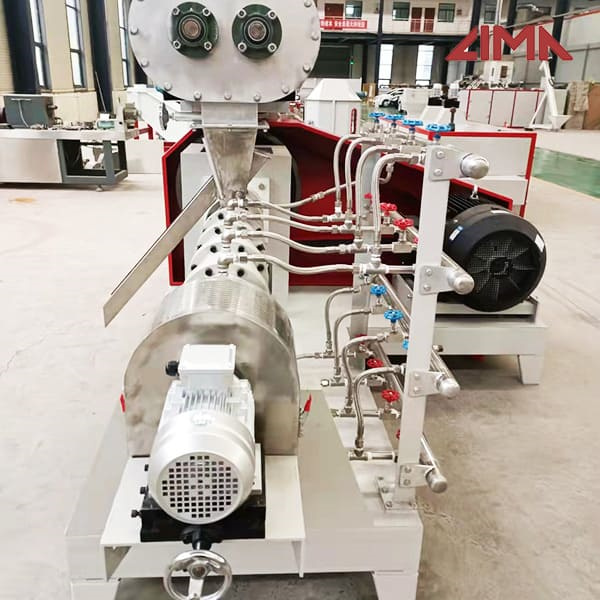

Go to see the wet-way pet food processing machines, floating fish feed extruder machines about 400-600 kg/h in LIMA. 2000 kg Brand Name: LIMA ... Pellet size: 0.9 ...

Dry-Type Feed Extruding Machine (250kg/Hour) - Afrimash2021/09/28 · Features of our Dry-Type Feed Extruding Machine. Dry-Type Feed Extruding Machine is especially beneficial for s + 8617337771729

Mar 23, 2021 · 200-1000kg/h Small-scale Poultry and Livestock Feed Production Line 1-18ton/h Ring Die Poultry Feed Pellet Making Machine 60-1000 kg/h Flat Die Poultry and Livestock Feed Pellet Making Machine 300-2000kg/h Floating Fish feed pellet automatic production line 40-300kg/h Floating Fish feed pellet small production line 180-4000kg/h Wet Way Floating

Poultry Feed Pet Food Feed Extruder/ Fish Pellet Granulator Machine/Floating Fish Feed Extruding Pellet Machine Project Price List; Product : Quantity: Min Price ($) Max Price ($) Small Pet Food Processing Machine Floating Fish Feed Pellet Extruder: 1 Set : US$1595: US$7776: Factory Price Single Screw Floating Fish Feed Extruder: 1 Set : US

Lima is pellet mill machine manufacturer, focus on fish feed making machine and poultry feed machine produce and design.The capacity is 30kg/h~5000kg/h Email: sale@limamachinery.com Tel: 8617337771729

Features of Wet Type Fish Feed Making Machine 1.This kind of fish feed extruder machine owns simple structure, wide application, and low noise. 2.It can improve the quality and floating time of the fish feed pellets. 3.Salmonellosis and bacterial infections of the raw materials will be eliminated after being processed by the high temperature