1.Floating fish feed pellet machine, also known as fish feed extruder machine, is used to process various kinds of grains into high-grade aquatic feed pellets for fish, crab, catfish, shrimps, etc. 2.This fish feed pellet machine has gained popularity in fish farmers.

The axial die perforation size range available from 0.8 to 5 mm with varying thickness up to 5 mm. It is possible to add cooling systems to screw driven extruders but these vary in efficiency at keeping the product cool during the process even though they may keep the equipment cool!

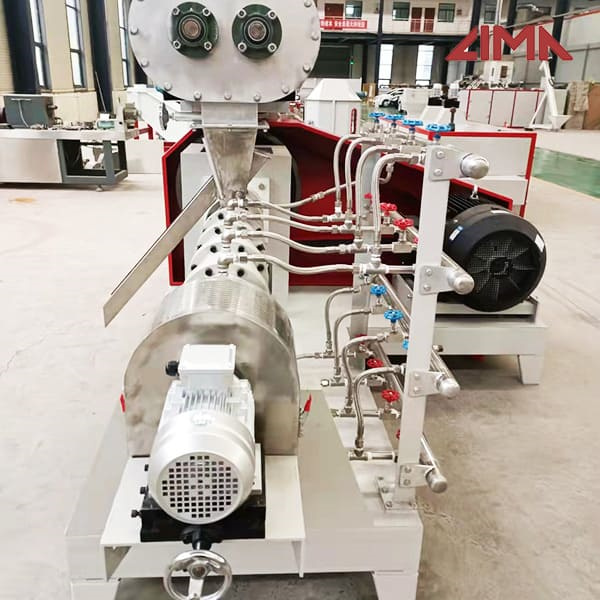

As Pet Food Extruder Machine manufacturers had designed High Quality Twin Screw pet Extruders used for pet food and fish feed production, developed and tested. The major components of the machine included the feeder hopper, the conditioning chamber (can be choose), the barrel that was a screw member housing and the screw with the die and die holder fitted at the extreme end of the barrel.Twin

High quality 70rpm Micro Twin Screw Laboratory Mixing Extruder from China, China's leading Twin Screw Laboratory Mixing Extruder product, with strict quality control 70rpm Micro Laboratory Mixing Extruder factories, producing high quality 0.75kw lab extruder machine products.

Twin screw extruder for . master batch production. Two stage extruder for PVC compound/high filler. PET recycled Plastic pelletizing machine. Lab extruder & Mini extruder. PVA+starch biodegradable granules making machine. Underwater pelletizer . for EVA compound. Nylon extrusion & Nylon compounding. Pet food extruder & extruded dog food

Twin Screw Food Extruder Machine Description. Twin Screw Extruder process developed by twin screw extruder manufacturers more then 30 years, enables the continuous production of highly homogeneous and finely structured products, using bio-sourced or synthetic raw materials. It is used to produce a wide range of Food & Feed products, our

KTS-250 Windsor PVC Pipe Plant. KTS-250 Windsor PVC Pipe Plant Die Head suitable upto 2000 mm pipes Die-pin bushes from 63mm to 200mm both 4kg & 6kg and 10kg SS Tank of 3mtr Traction unit upto 200mm TTU 200 Cuttin..

200KG-5T Wet Type Extruder Fish Feed Pellet Machine. Floating wet type extruder fish feed pellet machine also called Wet type fish feed extruder, which consists of feeding system, extruding system, peeling systems, heating system, transmission system, and control system. By employing advanced screw extrusion technology, it is widely preferred

for food twin-screw. screw extruder for the plastics industry. DZ series. Output: 400 kg/h - 3,000 kg/h. Screw diameter: 80 mm - 140 mm. Power: 85, 136, 140 kW. automatically controlled. The main motor, feeder, cutter, and liquid feed system of the extruder are all used for variable frequency speed adjustment.

Tilapia Fish Feed Extruder/pet Food Processing Machine/dog Food Production Line , Find Complete Details about Tilapia Fish Feed Extruder/pet Food Processing Machine/dog Food Production Line,Dog Food Production Line,Pet Food Processing Machine,Tilapia Fish Feed Extruder from Feed Processing Machines Supplier or Manufacturer-Anyang Ainuok Machinery Equipment Co., Ltd.

Jan 25, 2018 · twin-screw laboratory. pharma extruder. ZSE 18 HP-PH. Output: 0.2 kg/h - 5 kg/h. Screw diameter: 18 mm. Maximum speed: 1,200 rpm. ideal as a testing and production system suitable for throughputs of 200 g/h to 5 kg/h polished surfaces for easy cleaning. Compare this product Remove from comparison tool.

Apr 27, 2021 · In twin screw extruders, screws can be rotating either in the same (co-rotating) or opposite (counter-rotating) direction as shown in Figure 4. Two screws placed into the barrel side by side and it is designed to control operating parameters such as the filling level of material, the screw speed, the feed time and the residence time [ 30 ].

After-sales Service: One Year Warranty: One Year Power Source: Electric Process: Twin Screw Extrusion Automatic Grade: Automatic Application: Dog, Fish, Cat, Bird

USEON is a professional twin screw extruder machine manufacturer. We supply turn-key solutions to your compounding projects. This includes material handling, dosing, extrusion, pelletizing and other aspects. Through our expertise you will find suitable solutions to your compounding system needs. More than 2500 compounder installed.

31000 kg [70000 lb] * – Standard Machine Configuration: 1 Feed Barrel, 9 Solid Barrels (6 Aluminum, 3 Bronze/Cast Iron), 1 Vent Barrel, Gear Box Lube 40mm and Up, Barrel Cooling Pump, Main Motor Blowers 400hp and Up