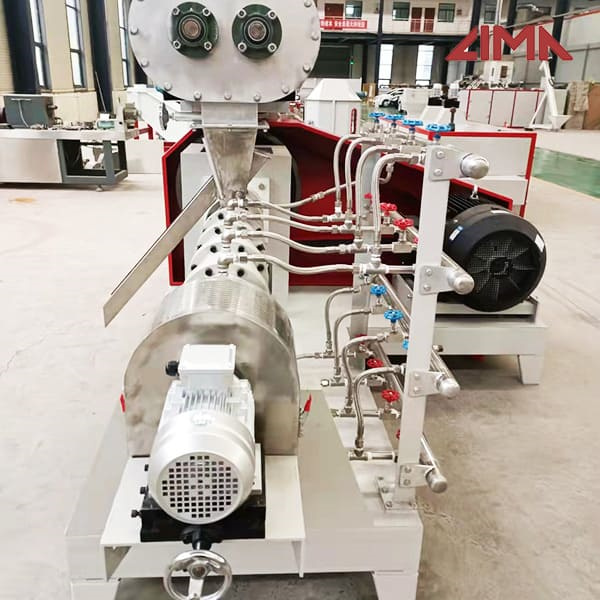

The fish feed is extruded through the mould and different particle sizes and shapes of fish feed can achieved by changing mould. The capacity of twin-screw extruder can reach 0.5-1 ton per hour, especially is suitable for the production of 2-6mm floating particles. The forming rate of pellet feed is up to 99%.

Our company produces a variety of specialised diets and custom feed mixes for the poultry, dairy, ostrich and swine industries. Meadow Feeds also supplies a full range of technical services to its customers, including advice on nutrition, feeding programs, animal husbandry and production techniques.

•FFDAs enhanced the average productivity from 500 to about 2000 Kg/Ha/yr however the potential of technologies at 15 tonnes/Ha/yr. Fish production range under different culture systems Sl. No. Culture system Average production rates (T/ha/yr) 1 Composite fish culture 4-6 2 Intensive culture 10-15 3 Clarias culture 3-5 4 Sewage-fed fish 3-5 5

Home » Blog » Fish Feed Machines » 300kg/h fish feed production lines Feed size 1 mm in assam fish feed producing machine manufacturer, fish feed making Machine size (mm):1650*1400*1300mm Weight (kg):650kg View More + Floating Fish feed pellet machine By Dry Way Model :LM70 Capacity (kg/h):50-200kg/h Main power (kw):18.5kw Feeder power

Therefore, it is particularly important to select aquatic production equipment. Fish food divided into 2 kinds of fodder, the sinking fish feed and floating fish feed. This production line can produce aquaculture feed pellets such as squid, grass carp, squid, tilapia, ornamental fish, turtle, and bullfrog. Fish feed size range: 1mm, 1.5mm, 2.0mm-10mm.

Fish Feed Hammer Mill. 11kw/h. 300-400kg/h. 1350*930*1250mm. 240kg. 2.Mixing. Powdery feed materials need to be mixed thoroughly in the mixer to ensure a high-quality of nutritional feed. We provide feed mixer with a single-shaft and twin-ribbon. It reinforces convection, shearing, and mixing effects and is an essential parts of the whole line.

Jan 21, 2021 · Mean abundance of microplastics in fish destined whole for fishmeal production was 0.69 ± 0.81 items/specimen, ranging 0–2 items when broken down per species (Fig. 1). In the ‘wastes and by

The Summer Edition is equipped with an extra dose of natural antioxidants. These protect the body cells from oxidative stress, which results in immune stimulation, higher feed intake, improved weight gain, and efficient feed conversion. Summer Edition is part of Aller Aqua’s Temperature Adapted Feeds™ concept which helps ensure a higher

Calculate : (i) Power output of the turbine. (ii) Heat transfer per hour in the boiler and condenser separately. (iii) Mass of cooling water circulated per hour in the condenser. Choose the inlet temperature of cooling water 20°C and 30°C at exit from the condenser. (iv) Diameter of the pipe connecting turbine with condenser. Solution.

A production system is a collection of people, equipment, and procedures organized to perform the manufacturing operations of a company (or other organization) 4.1. Components of a production system: There are two components for a production system such as: 1.

(a) From Table 1, the Ratio of Concentration can be calculated as F/C = 100/10 = 10. If only assays are available, the ratio of concentration equals (20 – 0.1)/(2.09 – 0.1) = 10 So, for each 10 tons of feed, the plant would produce 1 ton of concentrate. (b) Using the example data from Table 1, the % Cu recovery calculated from weights and

Clextral. Technological innovation and internationalization have always been the driving forces of our growth, enabling us to become a recognized leader in twin screw extrusion. We manufacture food and feed production lines, security pumps and bring our expertise to Green industries and drying technologies. We believe in the power of twin screw

Pack Size: 1 Kg. Type On farm key factor of fish feed production; ... Advantages Strong binding ability and good stability Feed stable for 2-6 hours in water ...

4.2.2 Description of canning tuna in brine. The description is related to canning plant with a capacity of 20 tons whole raw fish (bluefin or yellowfin tuna) per 8 hours. The overall yield is approximately 50-55% which gives approximately 10 000 450 g (1 pound) cans or 20 000 225 g (1/2 pound) cans per 8 hours.

1 + .97 = $3.13 The second step is the calculation of the producer price in terms of whole fish, the product form the producer is supplying. To find the whole fish price, simply multiply P, by the appropriate yield from Table 1: (4) Pw = P 1 x Y where P w = Whole fish price paid to the producer P 1 = Producer's price based on the pro